-

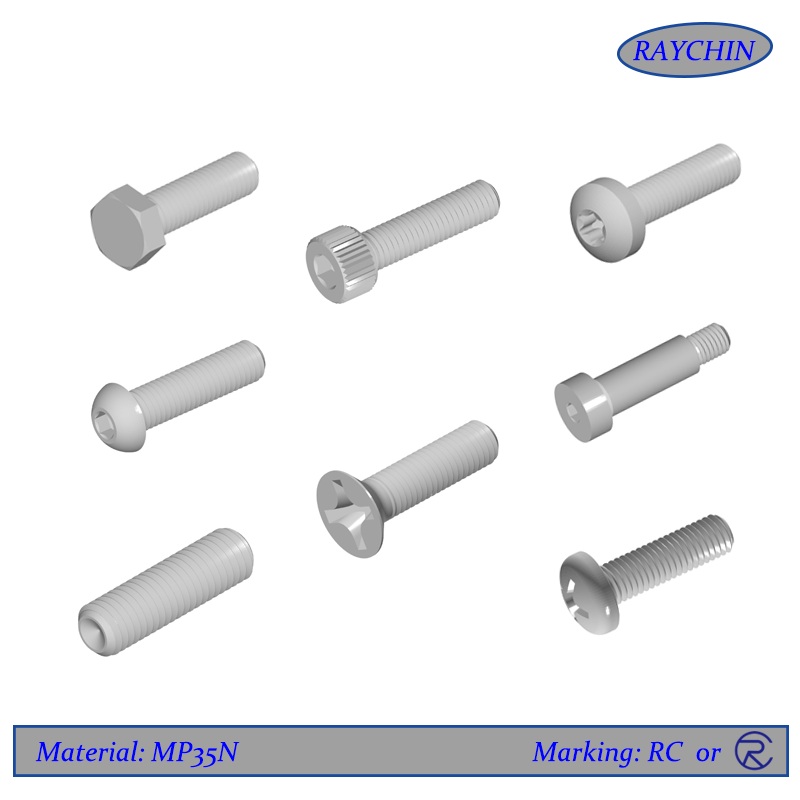

MP35N Fasteners

MP35N (2.4999) fasteners are known for their extraordinary strength and are the strongest fasteners we offer at RAYCHIN. MP35N fasteners owe their extraordinary strength to a unique alloy combination of nickel, cobalt, chrome and molybdenum and have ultimate tensile strengths that range from 227 ksi to 294 ksi (with age hardening).

Send Email Details

Beyond the strength of MP35N fasteners, they are also exhibit good corrosion resistance and can resist most mineral acids, hydrogen sulfide, seawater and salt spray environments.

MP35N fasteners are also resistant to high temperature oxidation and could operate in environments up to 800°F and still maintain much of its strength. -

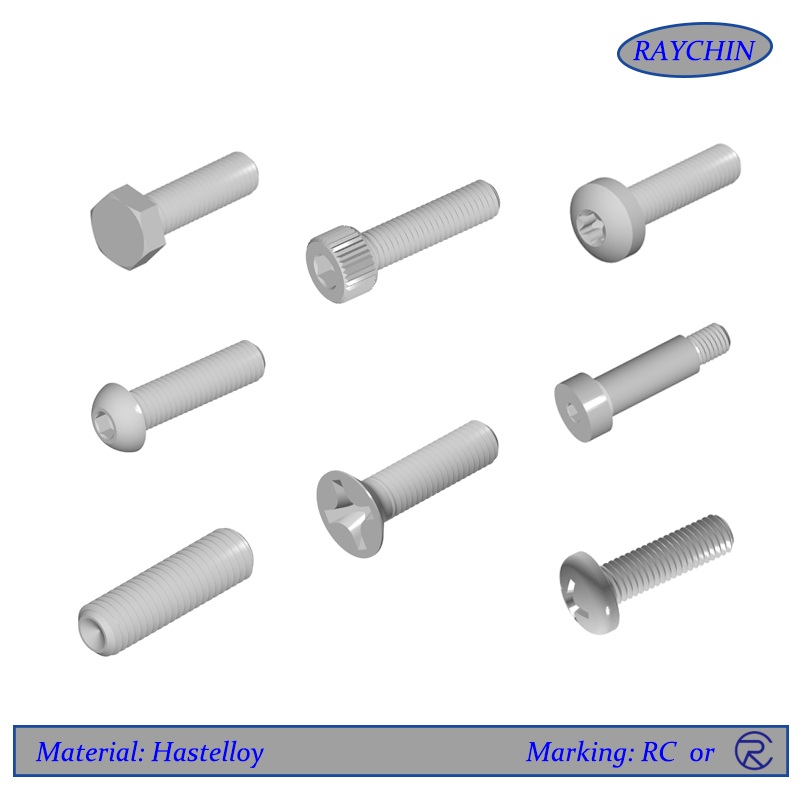

Hastelloy Fasteners

Hastelloy Fastener

Send Email Details

Hastelloy fasteners such as bolts, screw, nuts and threaded rods are ideally suited for a wide variety of medium to severe corrosive acid environments. The most common grade for Hastelloy fasteners is Hastelloy C276 (2.4819), which is the one of the most versatile of the corrosion resistant nickel alloys – exceeding that of Inconel or Monel. Hastelloy fasteners are also available in other specialty grades that can address more niche corrosion issues.

Hastelloy fasteners are resistant to some of the most severe chemicals, this very material often finds use in oil & gas sour gas service, chemical processing, power industries flue gas desulfurization systems, off-shore oil and down hole environments, pulp & paper bleaching and digesters, as well as other industrial facets where corrosion is an issue. -

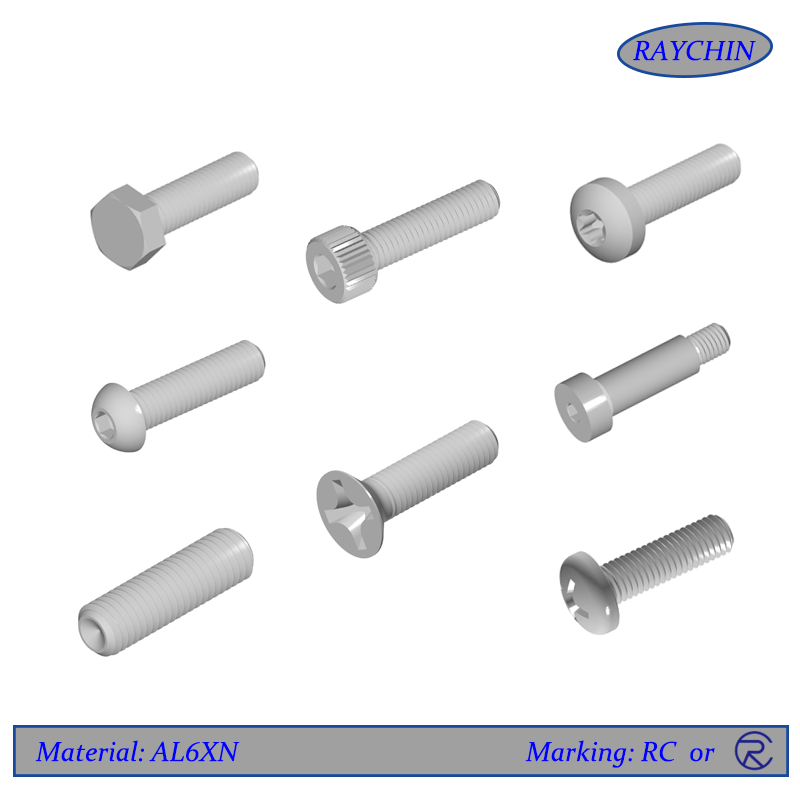

AL6XN Fasteners

Originally developed to combat sea water corrosion, AL6XN has expanded its role as being good mid-range corrosion resistant alloy. AL6XN fasteners are a low carbon, high purity, nitrogen-bearing "super-austenitic" stainless alloy. Also considered a 6-Moly alloy (6% Molybdenum), AL6XN bolts are similar in composition and capabilities to Alloy 926 and SMO 254. With a higher nickel and molybdenum content than Duplex 2205 and Super Duplex 2507, it delivers better corrosion resistance while giving a more cost effective alternative to nickel super alloys like Inconel or Hastelloy in moderately corrosive conditions.

Send Email Details -

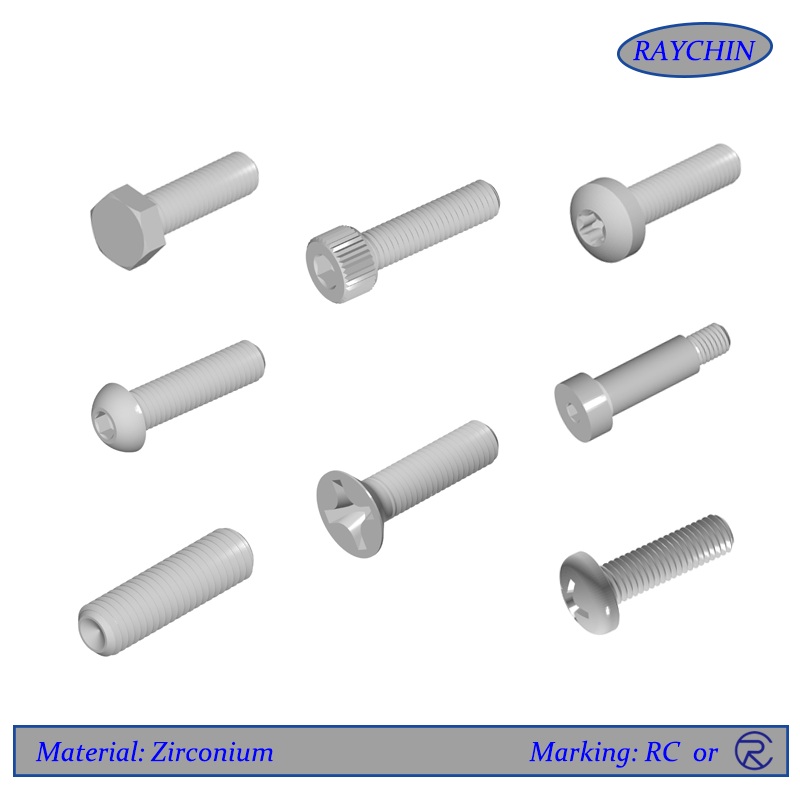

Zirconium Fasteners

Commercially pure zirconium screws, also known as zirconium 702, are most well-known for their superior corrosion resistance in some of the harshest environments that include:

Send Email Details

• Hydrochloric Acid• Sulfuric Acid• Formic Acid• Nitric Acid • Acetic Acid

It is also a metal that offers industry unique properties. It does not absorb neutrons, making it ideal for use in nuclear power and at low temperatures it is superconductive, making it ideal for super magnets.

Hydrochloric Acid Resistance

What makes Zirconium screws particularly useful to industry is their resistance to hydrochloric acid where they exhibit a corrosion rate of less than 5mpy at all concentrations and temperatures in excess of the boiling point. Even in 37% HCI, Zirconium screws do not begin to show substantial corrosion until 130°C (266°F). This performance is unmatched by any other engineering metal or alloy with the exception of tantalum. To give you a point of reference, Hastelloy C276 will experience 288 mpy (mils per year) of corrosion in just 10% HCl at the boiling point while Zirconium screws will have a nil corrosion rate even when aerated. As a result, Zirconium screws are most beneficial when used is in hydrochloric acid processes with temperatures above the boiling point and in the absence of oxidizing impurities. -

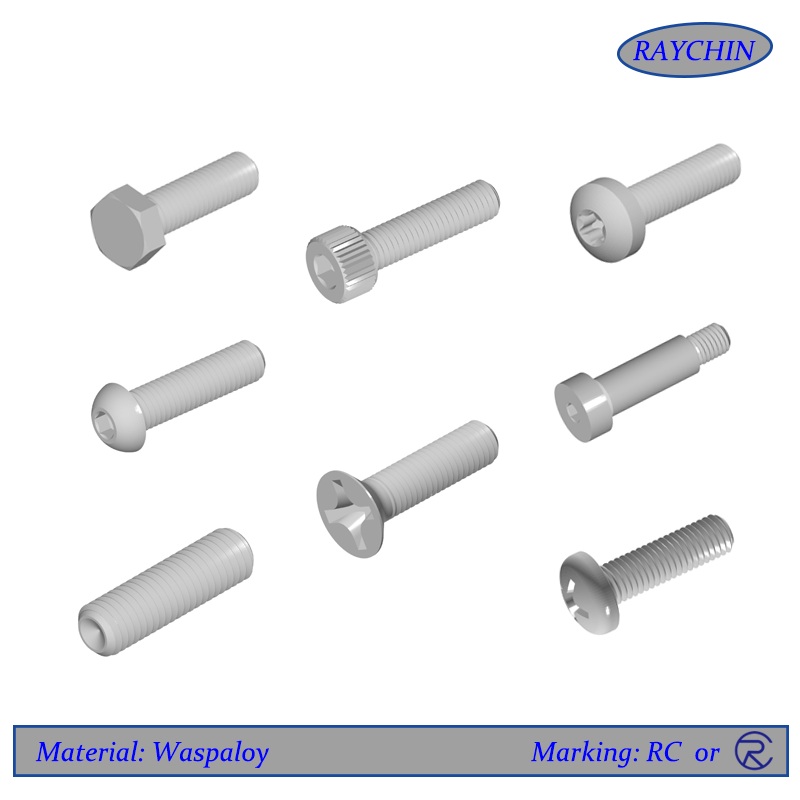

Waspaloy Fasteners

Waspaloy (2.4654) fasteners are known for their superb high strength at elevated temperatures. Waspaloy is a high performance nickel alloy combined with cobalt, chrome and molybdenum to create it’s unique combination of strength and high temperature stability.

Send Email Details

Similar to that of Inconel 718 fasteners, Waspaloy fasteners exceed the strength and stability of Inconel 718 at elevated temperatures beyond 1400°F. In addition, the oxidation resistance of Waspaloy fasteners make it an ideal materials for high temperature applications like gas turbines engines, and a variety of other aerospace components. -

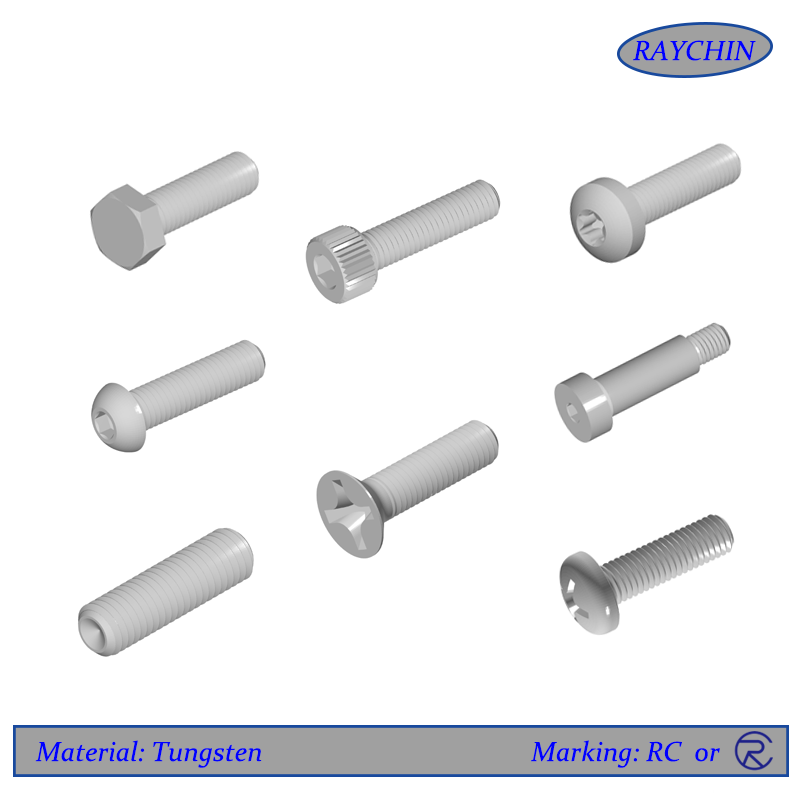

Tungsten Fasteners

Tungsten fasteners are known for their extreme high density; because of this unique attribute, they are often used for balancing rotating parts. Tungsten’s high mass also makes these fasteners radiopaque. This allows tungsten fasteners to block radiation and show up well on x-rays – even better than lead. Another unique attribute of tungsten is its extrmely high melting point of 3420°C. The high temperature stability of tungsten fasteners make them ideal for some of the hottest vacuum furnace environments. Beyond their high mass and temperature stability, tungsten fasteners are also very corrosion resistant.

Send Email Details

Tungsten fasteners are usually made from tungsten alloys per ASTM B777, and range from 90% to 97% pure tungsten, alloyed with nickel and copper or nickel and iron. Fasteners can also be made from Commercially Pure (CP) Tungsten. -

Titanium Fasteners

Titanium fasteners are best known for being strong, lightweight, and corrosion resistant. They are critical to many industries including chlor alkali, marine, off-shore oil & gas, desalination, medical, and pulp and paper. Grade 2 and 5 are the most commonly used grades of titanium screws:

Send Email Details

• Grade 2 (UNS R50400 / 3.7035) :Commercially pure titanium and the most common grade for screws.

• Grade 5 (UNS R56400 / 3.7165): Superior strength-to-weight ratio for a unique combination of corrosion and high strength. -

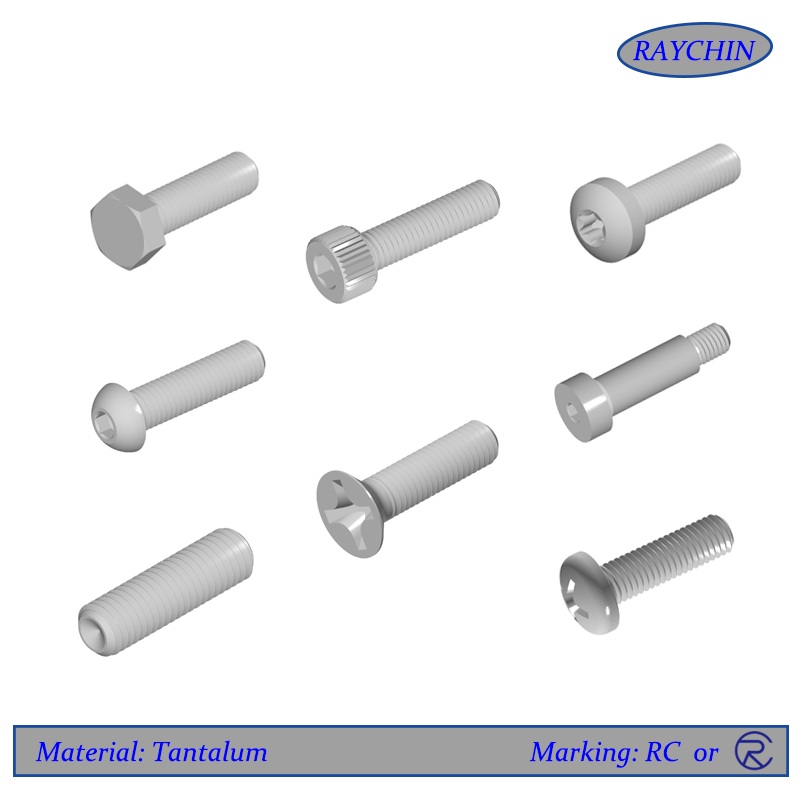

Tantalum Fasteners

Tantalum fasteners are best known for its unmatched corrosion resistance and chemical inertness. Tantalum fasteners have a similar corrosion resistance to that of glass, but all of the typical mechanical and electrical properties of a metal.

Send Email Details

Tantalum fasteners are also extremely stable at high temperatures, since tantalum has a melting point around 3000°C. High temperature applications require vaccum or inert gas since tantalum may embrittle when used in oxygen rich environments above 250°C. Tantalum fasteners are also one of the most bio-compatible metals available and is also radio-opaque due to its high density (16.68 g/cm3).

All tantalum fasteners are available in commercially pure tantalum and tantalum 2.5% tungsten (Ta-2.5%W). -

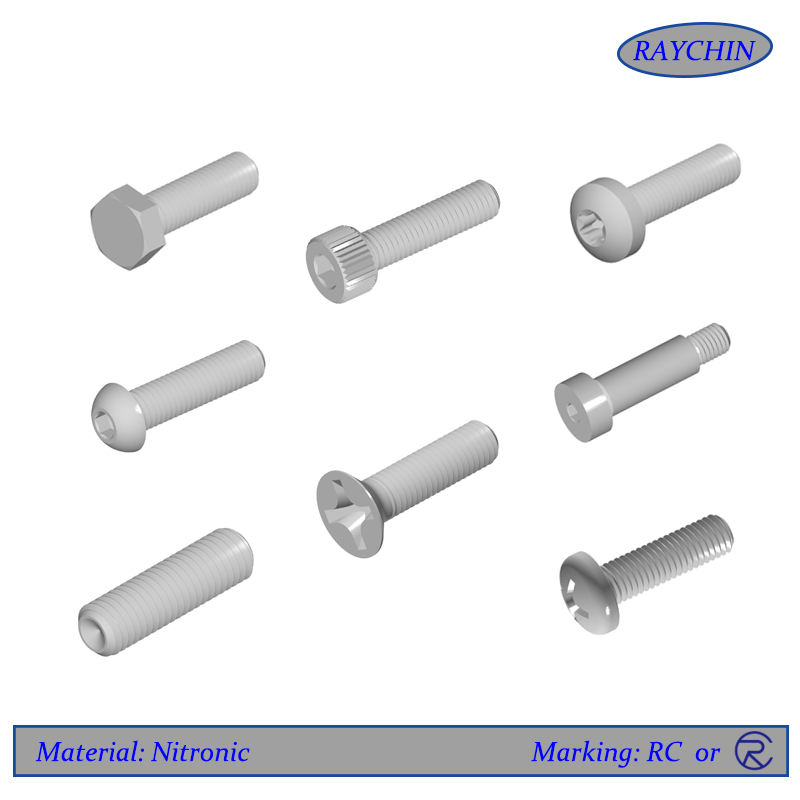

Nitronic Fasteners

Nitronic is a high strength austenitic steel alloy that was designed for high temperature use. It offers good high temperature properties as well as good low-temperature impact resistance. In addition, Nitronic bolts also offer nearly double the yield strength of 300 series stainless steel. Nitronic fasteners are available in two alloy variations, Nitronic 50 and Nitronic 60, each offering different niche capabilities.

Send Email Details