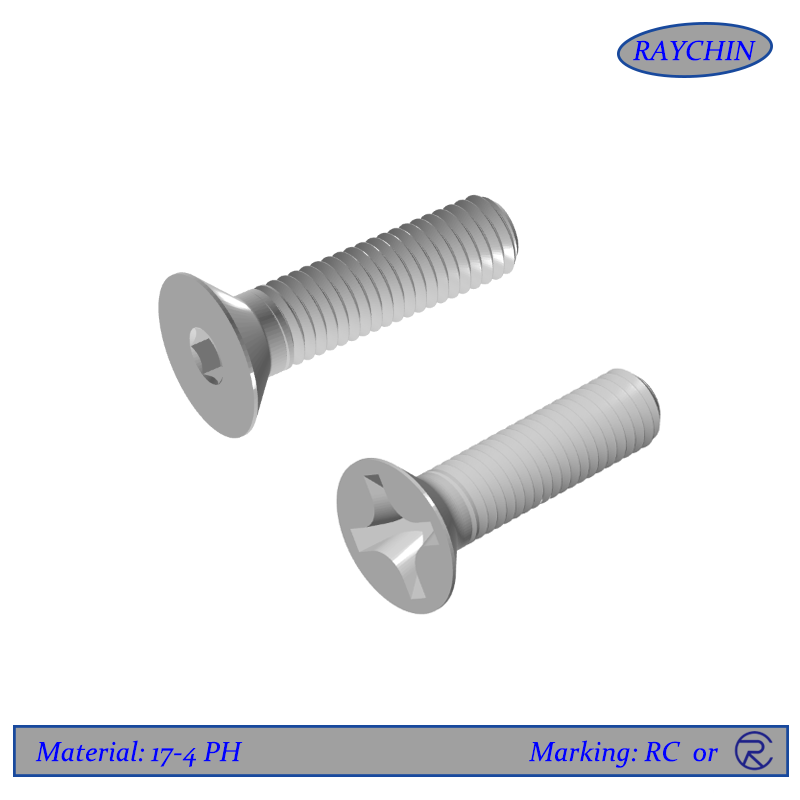

17-4 PH Flat Head Screws

17-4 PH Flat Head Screws

17-4 PH flat head screws are made from a precipitation hardened stainless steel most known for its exceptional strength and its ability to maintain its mechanical properties to 600°F. Compared to 316 stainless steel, 17-4 PH flat head screws yield strength is up

over 4 times greater. When compared to Duplex 2205 screws, the yield strength of 17-4 PH can be up to 2-½ times greater.

17-4 screws are available in 8 different aged (precipitation hardened) conditions offering a variety of mechanical properties.

An extremely strong precipitation hardened stainless steel

· Well suited for high strength applciaitons

· Up to 4x stronger than 316 stainless steel

· Maintains its mechanical strength up to 600°F

· 17-4PH Chemistry & Specifications

· 17-4PH flat head screw features and benefits

· 17-4PH Datasheet

Resources: 17-4PH Torque Specs

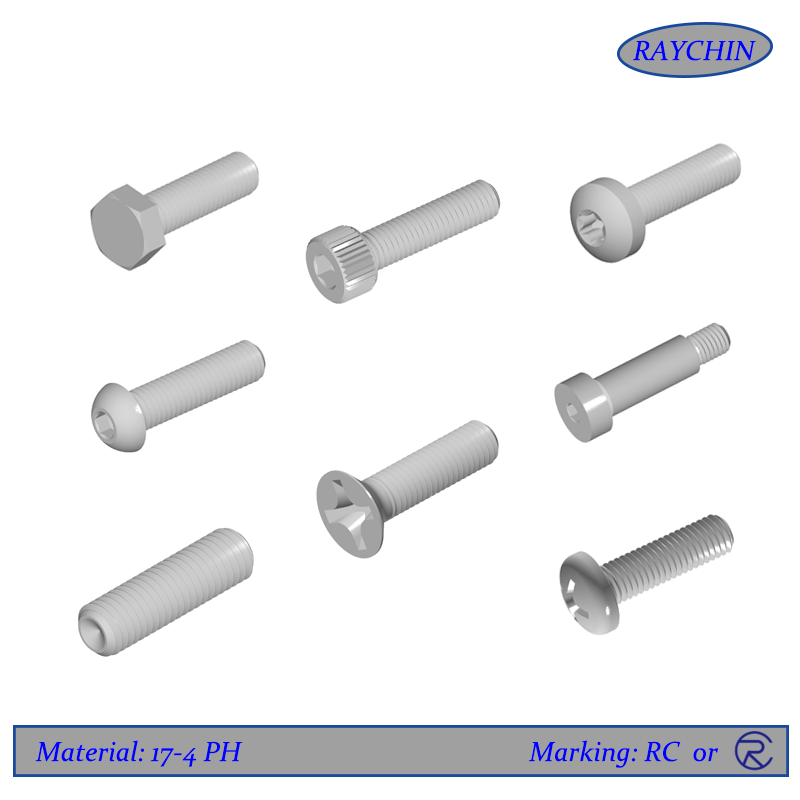

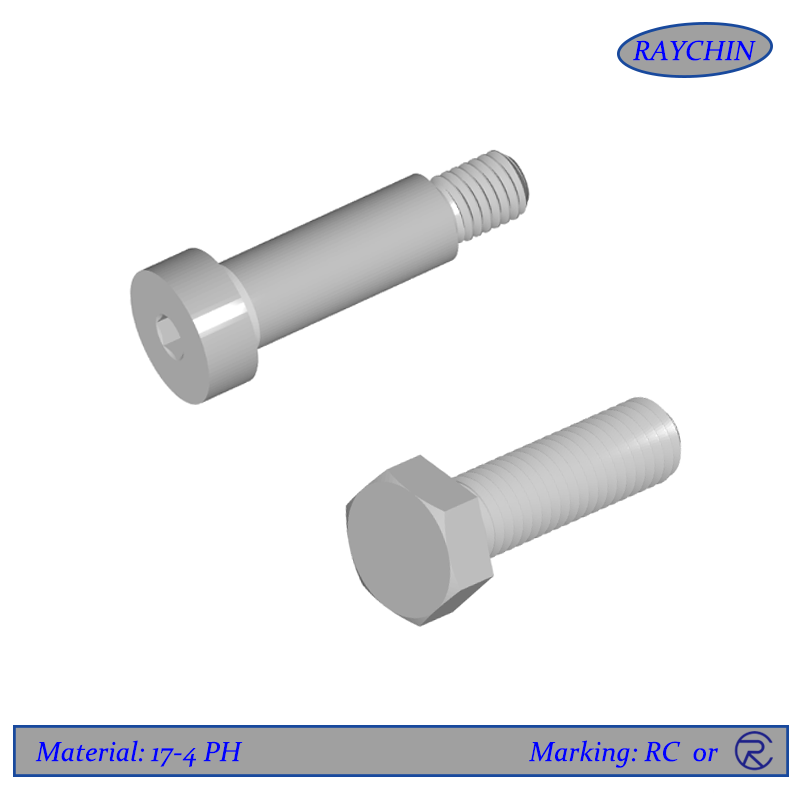

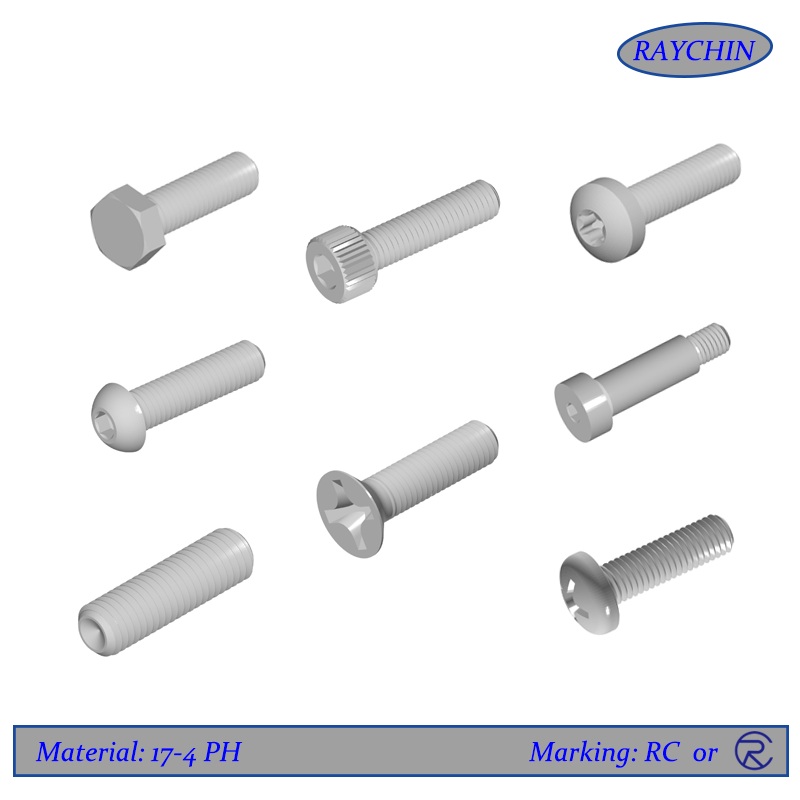

17-4 PH Screw Types: 12 Point Screws, Button Head Cap Screws, Flat Head Screws, Hex Cap Screws, Pan Head Screws, Set Screws, Socket Head Cap Screws, Tamper Resistant Security Screws, Torx Screws, Vented Screws

17-4PH Flat Head Screw Features and Benefits

17-4PH flat head screws are characterized by having a head with a top flat surface (which can feature either a slotted, phillips or allen driver) and bottom that is cone shaped or countersunk. With this design, the head of the screw can align flush or below the surrounding surface having obvious benefits.

17-4PH Slotted vs. Phillips Driver

Slotted Head Advantages | Phillips Head Advantages |

· Slotted head screws tend to strip less than Philips, especially in harsh environments · Slotted heads are typically better in applications where it's going to be unscrewed and re-done periodically, as the head tends to wear less. · In dirty environments, a flat head is much easier to clean out | · Phillips head offers a much stronger joint since it can tolerate more torque. |

Countersink Angle

For most flat head screw designs the angle of countersink is usually 82° for UNC and UNF applications however other angles ranging from 60° -120° could be specified.

Thread Type | Normal Flat Head Countersink Angle |

UNC / UNF | 82° |

Aerospace | 100° |

ISO Metric / Imperial | 90° |

17-4PH Chemistry & Specifications

17-4PH Specifications: UNS S17400, AISI 630, ASTM A564-630, Werkstoff 1.4542, AMS 5604 Sheet, Strip and Plate, ASTM A 693 Plate

17-4PH | Fe | Cr | Ni | Cu | Mn | Si | Mo | Nb+Ta | C | P | S |

Min% |

| 15.0 | 3.0 | 3.0 | - | - | - | - | - | - | - |

Max% | Bal | 17.5 | 5.0 | 5.0 | 1.0 | 1.0 | 0.50 | 0.45 | 0.07 | 0.04 | 0.03 |

ASTM F593, Grade 630

This specification covers seven groups of stainless steel alloys, with ASTM F593, Grade 630 applying 17-4PH. ASTM F593 Grade 630 covers the requirements for 17-4PH stainless steel bolts, hex cap screws, and studs sized 0.25 to 1.50 inches, inclusive, in nominal diameter. It is intended for common use and for service applications requiring general corrosion resistance.

| Full-Size Tests | Machined Specimen Tests |

Stainless Steel Alloy Group | Condition | Alloy Mechanical Property Marking | Nominal Diameter (inches) | Tensile Strength (ksi) | Yield Strength (ksi) | Rockwell Hardness | Tensile Strength (ksi) | Yield Strength | Elongation % |

7(630) | AH | F593U | 1/4 to 1.5 IN | 135 to 170 | 105 | C28 to38 | 135 | 105 | 16 |

Common 17-4 Fastener Conditions: Aged Conditions vs Tensile Strength

Aged Condition | Ultimate Tensile (ksi) | Yield Strength at 0.2% Offset (ksi) | Elongation % | Hardness Rc |

H900 | 200 | 185 | 14 | 40-47 |

H925 | 190 | 175 | 14 | 38-45 |

H1025 | 170 | 165 | 15 | 35-42 |

H1075 | 165 | 150 | 16 | 33-39 |

H1100 | 150 | 135 | 17 | 32-38 |

H115C | 145 | 125 | 19 | 28-37 |

H1150-M | 125 | 85 | 22 | 26-36 |

Annealed | 160 | 145 | 5 | ~35 |