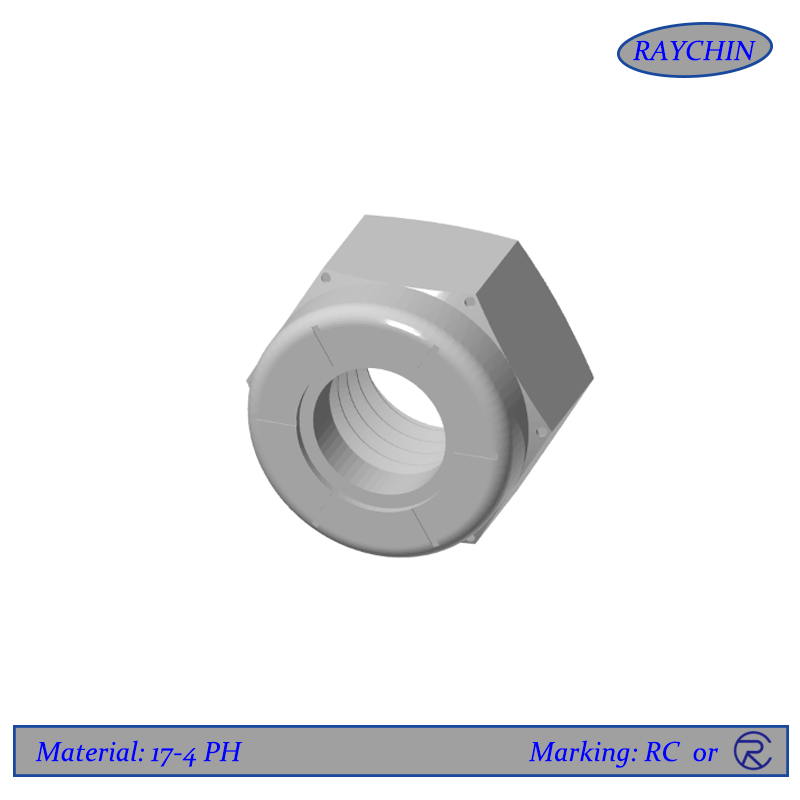

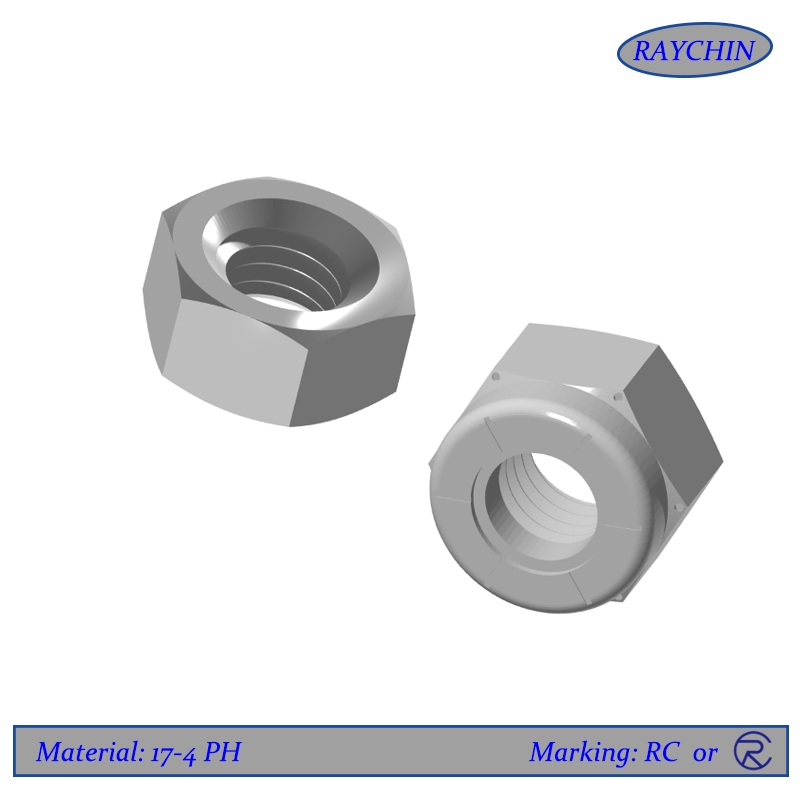

17-4 PH Lock Nuts

17-4 PH Lock Nuts

17-4 PH lock nuts are made from a precipitation hardened stainless steel most known for its exceptional strength and its ability to maintain its mechanical properties to 600°F. Compared to 316 stainless steel, 17-4 PH lock nuts yield strength is up over 4 times greater. When compared to Duplex 2205 nuts, the yield strength of 17-4 PH can be up to 2-½ times greater.

17-4 lock nuts are available in 8 different aged (precipitation hardened) conditions offering a variety of mechanical properties

An extremely strong precipitation hardened stainless steel

•Well suited for high strength applciaitons

•Up to 4x stronger than 316 stainless steel

•Maintains its mechanical strength up to 600°F

•17-4PH Chemistry & Specifications

•17-4PH lock nut features and benefits

•17-4PH Datasheet

Resources: 17-4PH Torque Specs

17-4PH Locknut Features and Beneifts

A 17-4PH locknut resists loosening from vibrations and torque. One of the most common styles is a prevailing torque locknut. This kind of 17-4PH locknut has a prevailing torque feature which deforms elastically, preventing it from freely spinning like a standard nut.

The two most common and reliable forms of prevailing torque locknuts are the flexloc style and the polymer insert lock nut. A 17-4PH flexloc nut is all-metal in composition with a segmented collar that creates six “locking fingers,” that act as a spring. 17-4PH polymer insert lock nuts are often referred to as nylon insert locknuts, although various high performance polymers can be used for the screw threads to “bite into.” Both flexlock and polymer insert locknuts are available in both hexagonal and 12 point configurations.

All Metal Flexloc Lock Nut |  Polymer/Nylon Insert Lock Nut Polymer/Nylon Insert Lock Nut

|

· Can be used at high temperatures · Distributes load evenly due to the fact that it is manufactured as one solid piece. · Is THE most reliable all-metal self-locking nut. · As it is all metal, it is best for high temperature or corrosive applications · One of the only all-metal lock nuts that is certified to 15 cycles of prevailing torque – which is military standard. | ·Overall the most reliable locknut, with the only limitation of application temperature ·Best for low temp applications, typically less than 350°F ·Various polymers inserts available (Nylon, Vespel, PVDF, etc.) for higher temp. or corrosive applications. ·Excellent reusability – can reliably be re-used 15 times ·Eliminates galling and cold-welding common with exotic alloys |

Other all metal lock nuts available include the 17-4PH stover and elliptical styles. Though these styles are often a cheaper initial cost, they are less reliable than the flexloc style. As these styles delivering less prevailing torque cycles and often result in more failures, the flexloc style is a better investment for both reliability and cost savings.

17-4PH Chemistry & Specifications

17-4PH Specifications: UNS S17400, AISI 630, ASTM A564-630, Werkstoff 1.4542, AMS 5604 Sheet, Strip and Plate, ASTM A 693 Plate

17-4PH | Fe | Cr | Ni | Cu | Mn | Si | Mo | Nb+Ta | C | P | S |

Min% |

| 15.0 | 3.0 | 3.0 | - | - | - | - | - | - | - |

Max% | Bal | 17.5 | 5.0 | 5.0 | 1.0 | 1.0 | 0.50 | 0.45 | 0.07 | 0.04 | 0.03 |

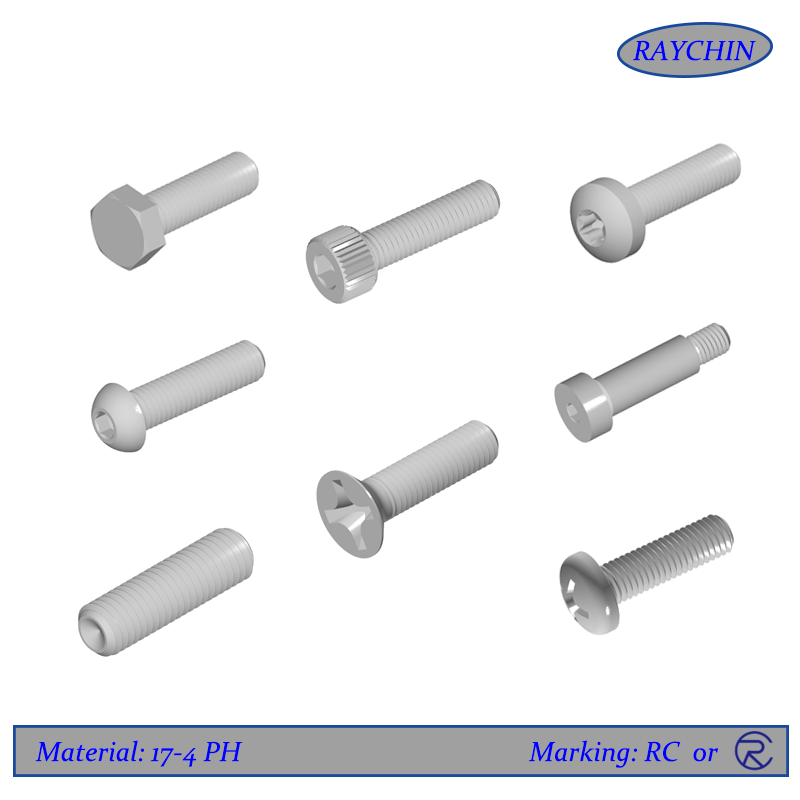

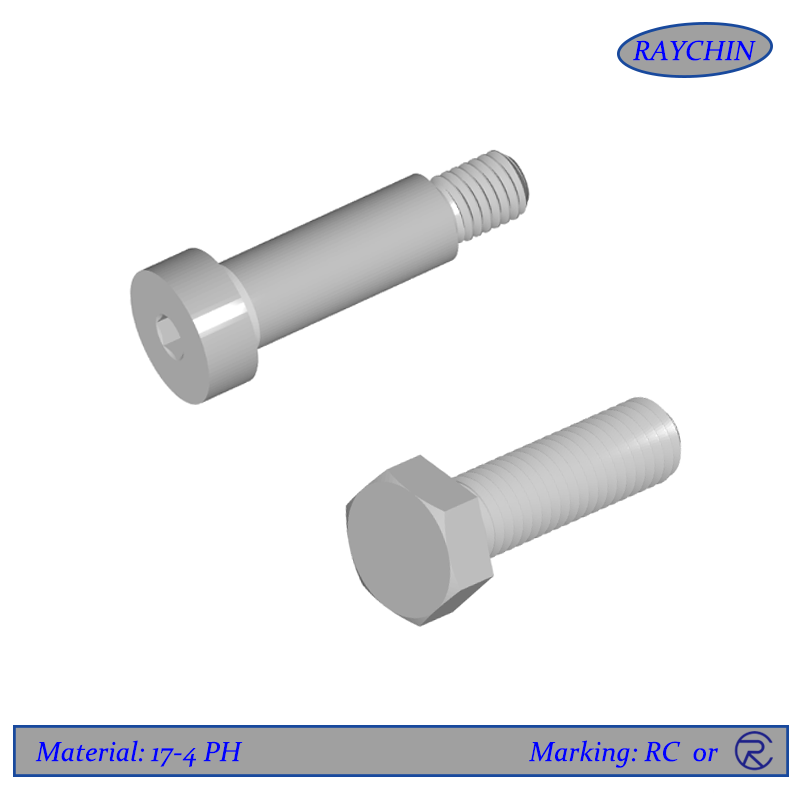

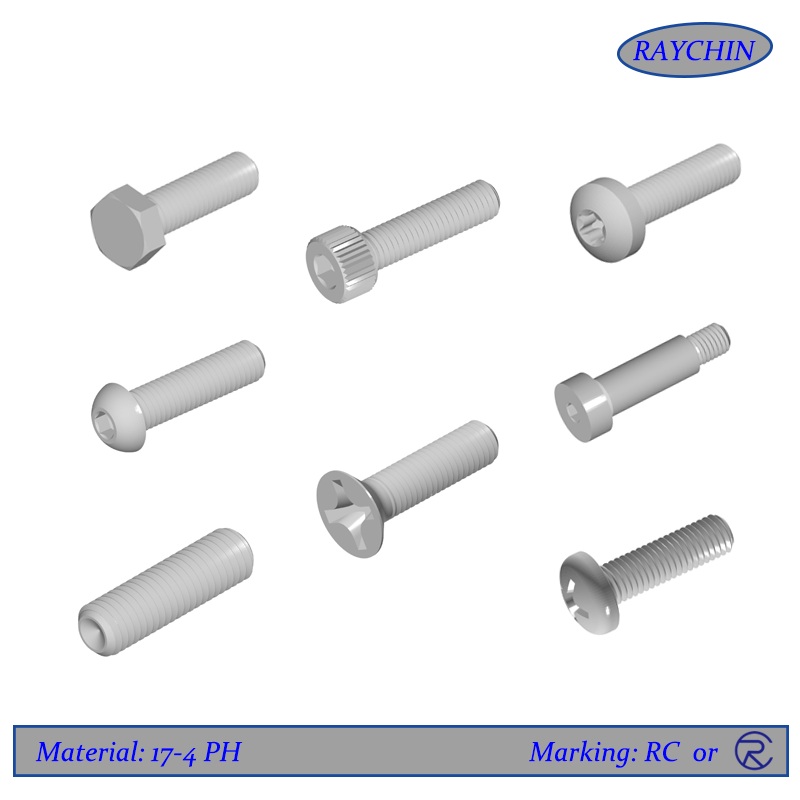

ASTM F593, Grade 630

This specification covers seven groups of stainless steel alloys, with ASTM F593, Grade 630 applying 17-4PH. ASTM F593 Grade 630 covers the requirements for 17-4PH stainless steel bolts, hex cap screws, and studs sized 0.25 to 1.50 inches, inclusive, in nominal diameter. It is intended for common use and for service applications requiring general corrosion resistance.

| Full-Size Tests | Machined Specimen Tests |

Stainless Steel Alloy Group | Condition | Alloy Mechanical Property Marking | Nominal Diameter (inches) | Tensile Strength (ksi) | Yield Strength (ksi) | Rockwell Hardness | Tensile Strength (ksi) | Yield Strength | Elongation % |

7(630) | AH | F593U | 1/4 to 1.5 IN | 135 to 170 | 105 | C28 to38 | 135 | 105 | 16 |

Common 17-4 Fastener Conditions: Aged Conditions vs Tensile Strength

Aged Condition | Ultimate Tensile (ksi) | Yield Strength at 0.2% Offset (ksi) | Elongation % | Hardness Rc |

H900 | 200 | 185 | 14 | 40-47 |

H925 | 190 | 175 | 14 | 38-45 |

H1025 | 170 | 165 | 15 | 35-42 |

H1075 | 165 | 150 | 16 | 33-39 |

H1100 | 150 | 135 | 17 | 32-38 |

H115C | 145 | 125 | 19 | 28-37 |

H1150-M | 125 | 85 | 22 | 26-36 |

Annealed | 160 | 145 | 5 | ~35 |