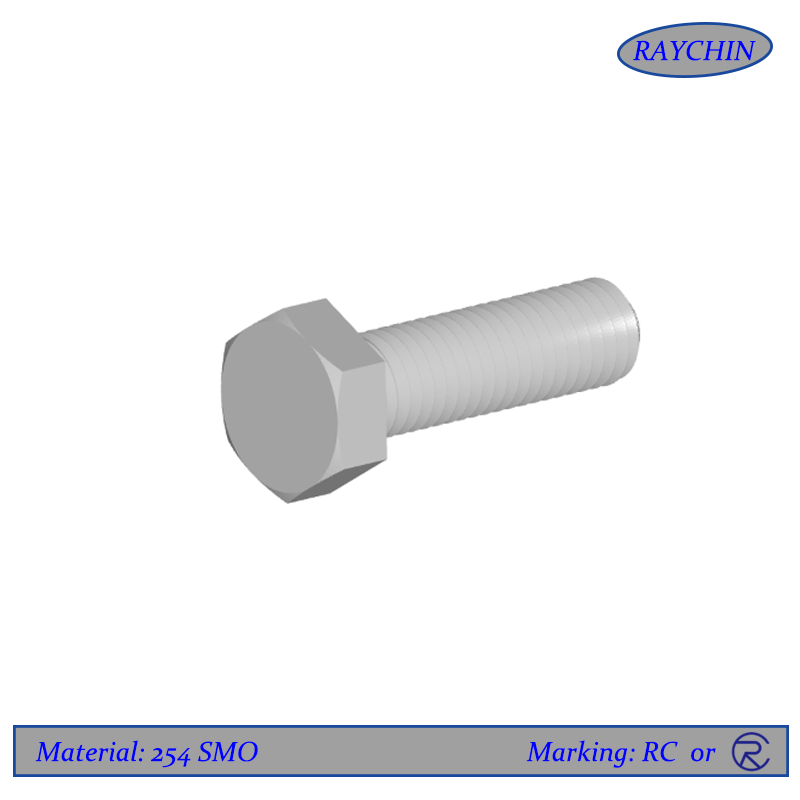

254 SMO Screws

Brand RAYCHIN

Product origin China

Delivery time 5-35 DAYS

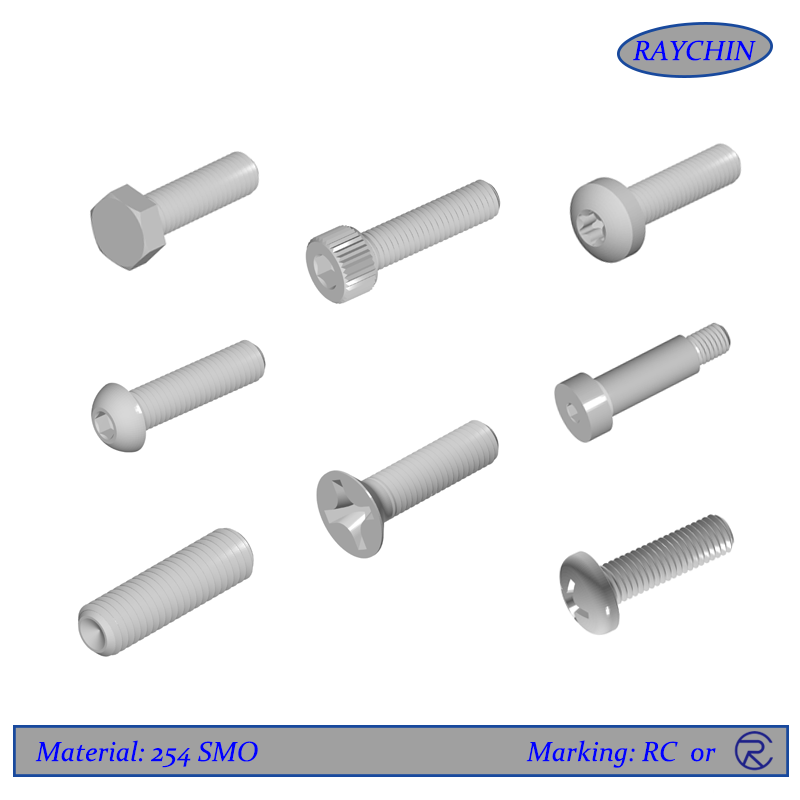

12 Point Screws254 SMO 12 point screws are ideal when you need higher torque than socket head cap screws offer. These screws are available in 1/4" diameter or larger. The only drawback is 12 point screws are less economical and require a higher minimum quantity due to the complexity of production.• IFI-115

• MIL SPEC

• DIN 34822

• DIN 34821

Button Head Cap ScrewsFor applications that require a wide clamping area and low profile fastener 254 SMO button head cap screws are a good choice. Button head screws are also used for fastening a material that is too thin to counter bore.• ASME B18.3

• ASME 18.3.4M

• DIN 7380 / ISO 7380

Flat Head Screws254 SMO flat head screws come standard with an 82° countersink angle. Other angles ranging from 60° -120° can also be made upon request. 254 SMO flat heads can be made with slotted or socket drivers. Phillips, torx and tamperproof drivers are also available depending on size, quantity and material.• ASME B18.3

• ASME B18.3.6

• DIN 963 / ISO 2009

• DIN 965 / ISO 7046

• DIN 7991 / ISO 10642

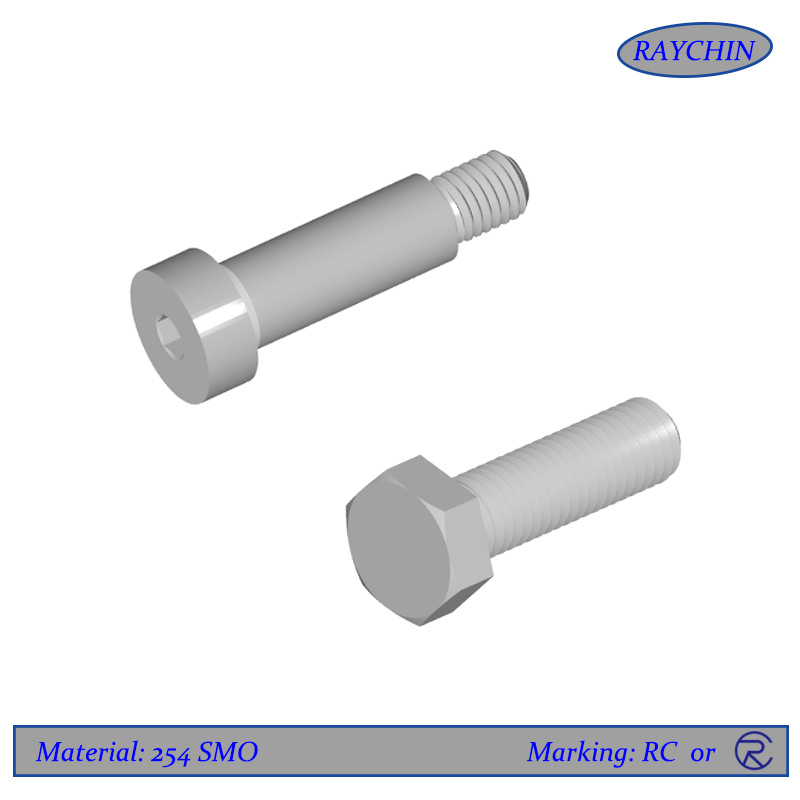

Hex Head Cap Screws254 SMO hex head cap screws are one of the most commonly used styles. They feature an added washer face that hex head bolt do not have. This washer face provides tighter dimensional tolerances. 254 SMO hex head cap screws provide high clamping force and easy access.• ASME B18.6.3

• DIN 931 / ISO 4014

• DIN 933 / ISO 4017

• DIN 961 / ISO 8676

Pan Head ScrewsPan head screws have a rounded head and most commonly have a slotted driver. 254 SMO pan heads are best for small diameter and low torque applications.• ASME B18.6.3

• DIN 7985

• DIN 921

• DIN 85 / ISO 1580

• DIN 84 / ISO 1207

(cheese head)

• DIN 966 / ISO 7047

(raised counter sunk)

12 Point Screws | 254 SMO 12 point screws are ideal when you need higher torque than socket head cap screws offer. These screws are available in 1/4" diameter or larger. The only drawback is 12 point screws are less economical and require a higher minimum quantity due to the complexity of production. | • IFI-115 |

Button Head Cap Screws | For applications that require a wide clamping area and low profile fastener 254 SMO button head cap screws are a good choice. Button head screws are also used for fastening a material that is too thin to counter bore. | • ASME B18.3 |

Flat Head Screws | 254 SMO flat head screws come standard with an 82° countersink angle. Other angles ranging from 60° -120° can also be made upon request. 254 SMO flat heads can be made with slotted or socket drivers. Phillips, torx and tamperproof drivers are also available depending on size, quantity and material. | • ASME B18.3 |

Hex Head Cap Screws | 254 SMO hex head cap screws are one of the most commonly used styles. They feature an added washer face that hex head bolt do not have. This washer face provides tighter dimensional tolerances. 254 SMO hex head cap screws provide high clamping force and easy access. | • ASME B18.6.3 |

Pan Head Screws | Pan head screws have a rounded head and most commonly have a slotted driver. 254 SMO pan heads are best for small diameter and low torque applications. | • ASME B18.6.3 |

254 SMO (1.4547) Chemistry & Specifications

254 SMO Specifications: UNS S31254, EN Number 1.4547

254 SMO | Fe | Cr | Ni | Mo | Cu | Mn | Si | N | P | C | S |

Min % | - | 19.5 | 17.5 | 6.0 | 0.5 | - | - | 0.18 | - | - | - |

Max % | Bal | 20.5 | 18.5 | 6.5 | 1.0 | 1.0 | 0.8 | 0.20 | 0.03 | 0.02 | 0.01 |

254 SMO Mechanical Properties

Properties | Metric | Imperial |

Tensile Strength | 680 Mpa | 98.6 ksi |

Yield Strength | 300 Mpa | 43.5 ksi |

Elongation at Break | 50% | 50% |

Modulus of Elasticity | 195 GPa | 28300 ksi |

Shear modulus | 75 GPa | 10900 ksi |

254 SMO Seawater Corrosion

Crevice Corrosion Tests in Seawater: Percentage of Sites Attached

UNS | % Sites Attacked | |

AL6XN | N08367 | 0% |

Hastelloy C276 | N10276 | 0% |

254 SMO | S31254 | 6% |

1925hMo | N08926 | 6% |

316 / 316L | S31603 | 75% |