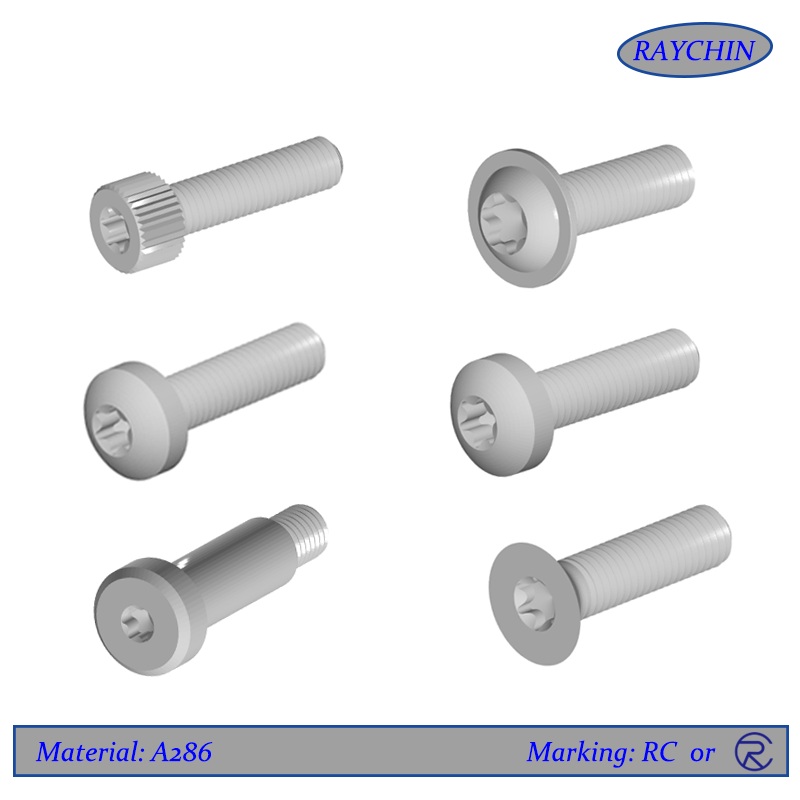

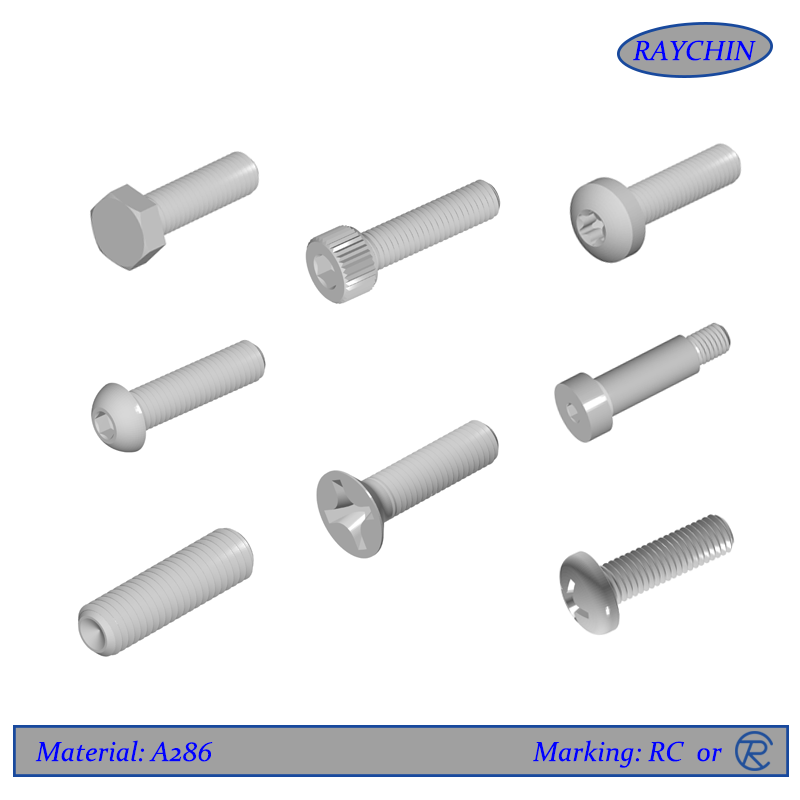

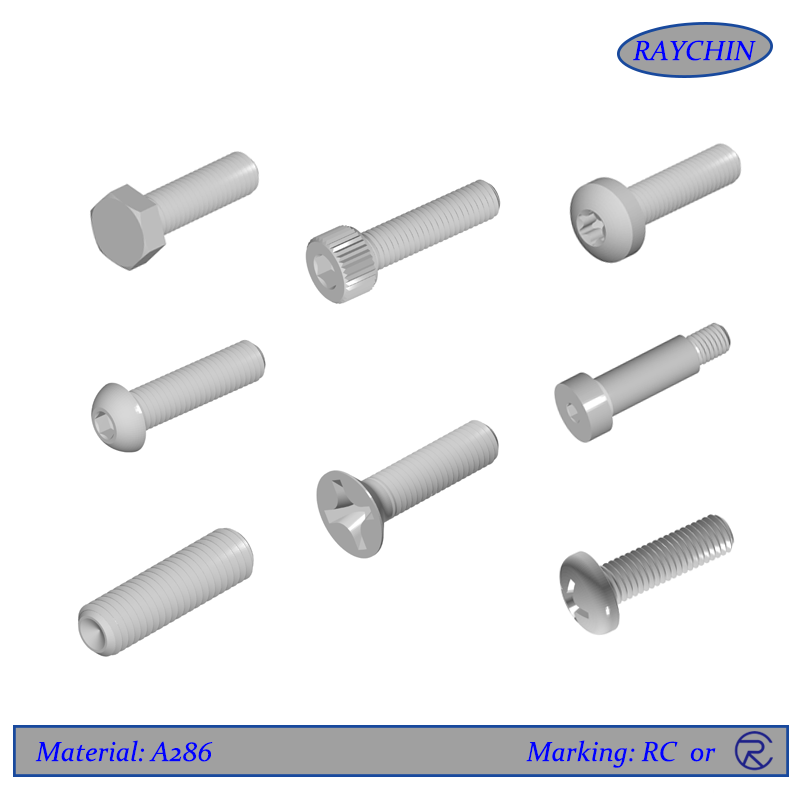

A286 Torx Screws

Brand RAYCHIN

Product origin China

Delivery time 5-35 DAYS

A286 screws, also known as Alloy 660 screws are stainless steel alloy which contains iron, nickel and chromium. A286 torx screws are known for their high strength, creep resistance and oxidation resistance at elevated temperatures once age hardened. As a result, A286 screws provide high levels of strength from room temperature up to about 1300°F (700°C).

A286 torx screws are also mildly corrosion resistant. While they should not be used for strong acid environments, they provide excellent oxidation resistance up to 1500°F (815°C) in conditions that would typically be found in high temperature exhaust streams. For the most critical applications, we offer bolts screws per ASTM A453 Grade 660. This ensures tensile and rupture properties.

A286 Torx Screws

A286 screws, also known as Alloy 660 screws are stainless steel alloy which contains iron, nickel and chromium. A286 torx screws are known for their high strength, creep resistance and oxidation resistance at elevated temperatures once age hardened. As a result, A286 screws provide high levels of strength from room temperature up to about 1300°F (700°C).

A286 torx screws are also mildly corrosion resistant. While they should not be used for strong acid environments, they provide excellent oxidation resistance up to 1500°F (815°C) in conditions that would typically be found in high temperature exhaust streams. For the most critical applications, we offer bolts screws per ASTM A453 Grade 660. This ensures tensile and rupture properties.

A286 / Alloy 660 for excellent high temperature oxidation resistance

· Good material for high temperature oxidation resistance

· Maintains high strength at elevated temperatures

· Specifications and heat treatments

· ASTM A453 Grade 660

· A286 chemistry

· Datasheet for A286

Applications

Because of the properties of Alloy 660 / A286 these torx screws are often found in high temperature engine, manifold, exhaust and turbine applications as well as off-shore oil & gas applications. In addition, A286 / Alloy 660 is also non-magnetic and finds a niche in non-magnetic cryogenic equipment.

Resources: A286 Torque Specs

Screw Types: 12 Point Screws, Button Head Cap Screws, Flat Head Screws, Hex Cap Screws, Pan Head Screws, Set Screws, Socket Head Cap Screws, Tamper Resistant Security Screws, Torx Screws, Vented Screws

Property | Continuous Operation | Short Term / Intermittent Use |

High Strength Retention | -320°F up to 1000°F | 1300 -1500°F |

Oxidation Resistance | 1500°F | 1800°F |

Applications

Because of the properties of Alloy 660 / A286, these bolts are often found in high temperature engine, manifold, exhaust and turbine applications as well as off-shore oil & gas applications. In addition, A286 / Alloy 660 is also non-magnetic and finds a niche in non-magnetic cryogenic equipment. Extreme Bolt & Fastener also provides A286 to ASTM A453 Grade 660 specification. This specification ensures accurate standards for tensile and stress rupture properties, which is critical for many high temperature applications.

Resources: A286 Torque Specs

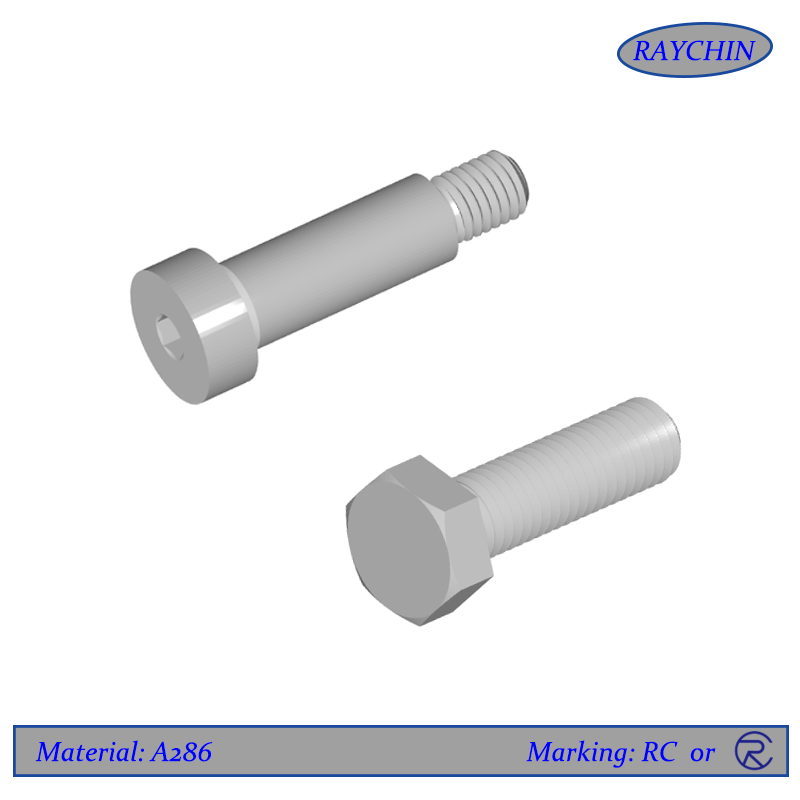

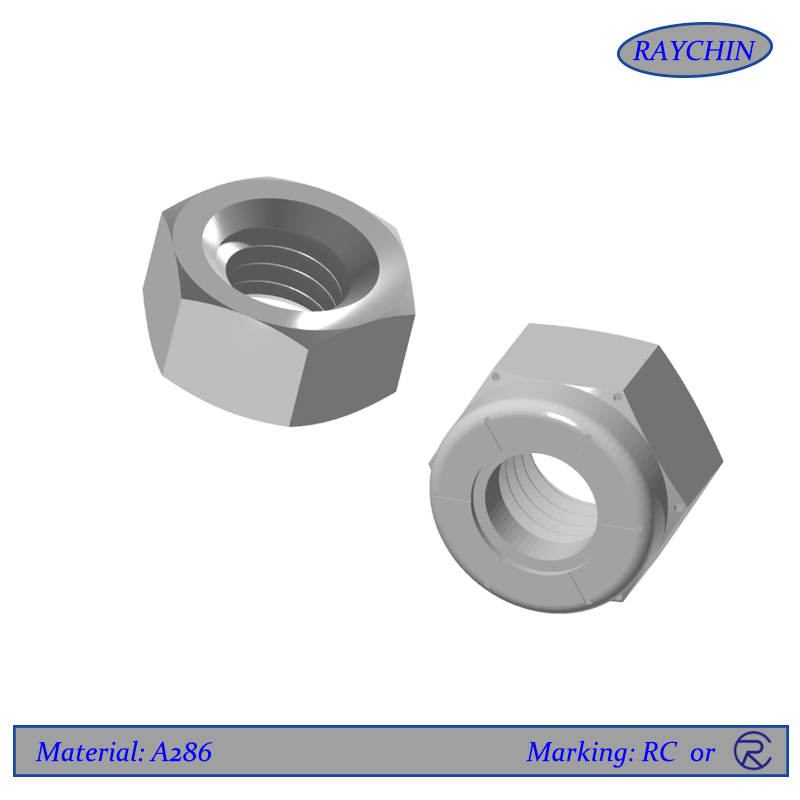

Bolt Types Available: Hex Bolts, Shoulder Bolts

Property | Continuous Operation | Short Term / Intermittent Use |

High Strength Retention | -320°F up to 1000°F | 1300 -1500°F |

Oxidation Resistance | 1500°F | 1800°F |

ASTM A453 Grade 660

Material specification ASTM A453 Grade 660 applies to bolts, studs, nuts and other fasteners. It ensures fasteners meet strength standards for use in high temperature bolting applications. ASTM A453 Grade 660 is classified into 4 property classes / heat treatments: A, B, C & D, each designated with different tensile and stress rupture properties. The most common of the ASTM 453 classes are class A or D. The grades A, B and C all have the same minimum tensile strength and minimum yield strength of 130ksi and 85ksi respectively. However grade D has a significantly better yield with a min tensile of 130ksi and a min yield of 105ksi.

Additional A286 / Alloy 660 Specifications, Cold Working & Heat Treatments (1.4980)

AMS A286 / Alloy 660 Heat Treatments

By AMS numbers, the most common for A286 / Alloy 660 is AMS 5737 (same as Grade A) and then AMS 5732 (same as Grade B).

A286 / Alloy 660 Cold Worked Fasteners

For additional strength, A286 could be aged and cold worked to achieve a min ultimate tensile strength of 160ksi upon request.

Additional Specifications

UNS S66286, ASTM A453, AMS 5525, AMS 5726, AMS 5732, AMS 5737, AMS 5804, EN 1.4980, GE B50T1181, GE B50T12, GE B50T81, Werkstoff 1.4980, ASTM F2281

A286 / Alloy 660 Chemistry

A-286 | Fe | Ni | Cr | Ti | Mn | Mo | Si | Co | Va | Al | C | P | S | B |

Min% | - | 24.0 | 13.5 | 1.9 | 1.0 | 0.1 | 0.003 | |||||||

Max% | Bal | 27.0 | 16.0 | 2.35 | 2.0 | 1.5 | 1.0 | 1.0 | 0.5 | 0.35 | 0.08 | 0.025 | 0.025 | 0.01 |

Mechanical Properties

Material Condition (Grades A-D per ASTM A453) | Ultimate Tensile (ksi) min | Yield Strength at 0.2% Offset (ksi) min | Elongation % | RA% min |

A | 130 | 85 | 15 | 18 |

B | 130 | 85 | 15 | 18 |

C | 130 | 85 | 15 | 18 |

D | 130 | 105 | 15 | 18 |

Cold Worked | 160 | 120 | 12 | 18 |