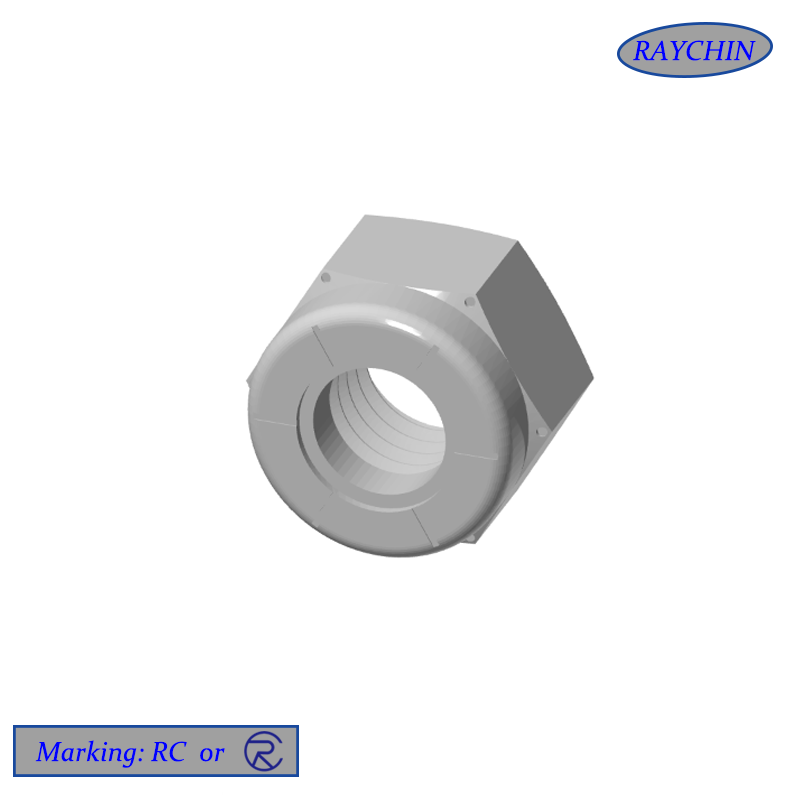

Lock Nuts

Brand RAYCHIN

Product origin China

Delivery time 5-35 DAYS

Lock Nuts

RAYCHIN is a manufacturer and worldwide supplier of standard & custom fasteners(Lock Nuts) including those manufactured from the following materials: Hastelloy® C-276, Hastelloy® C-22, Hastelloy® B-2, Hastelloy® G-30, Monel® 400, Monel® K-500, Inconel® 600, Inconel® 625, Inconel® 718, Incoloy® A-286, Titanium Grade 2, Titanium Grade 5, Titanium Grade 7, Nickel 200, Nickel 200, Aluminum, Molybdenum, Nimonic, Nitronic, Tantalum, Tungsten, Waspaloy, Zirconium, Duplex S31803, Duplex S32205 and Super Duplex S32750, etc.

Lock Nuts

The lock nut is a nut widely used in machinery and other industries. Its working principle is to use the friction between the nut and the bolt for self-locking. However, the reliability of this self-locking will be reduced in dynamic loads. In some important occasions, we will take some anti-loose measures to ensure the reliability of the nut locking

Lock Nut Sizes

• #00 - 10"

• M1.2 - M250

Lock Nut Specifications

• ASME B18.16.3M

• DIN 980

• DIN 6923

• DIN 985

• DIN 986

• ISO 7042

• ISO 19513

• ISO 4161

• ISO 10511

• ISO 7040

All Metal Fle xloc Lock Nut xloc Lock Nut |  Polymer/Nylon Insert Lock Nut Polymer/Nylon Insert Lock Nut |

|

|

RAYCHIN Lock Nuts are manufactured by the cold heading and hot forming technologies We offer fasteners in both USCS/Imperial and metric sizes.

RAYCHIN’s advanced and comprehensive range of capabilities include engineering, R&D, prototyping, custom manufacturing, precision processing and testing. All RAYCHIN materials are sourced from the most reputable and exacting foundries in the world. We maintain a multi-million-dollar inventory of fasteners in our product warehouse, which enables RAYCHIN to select, package and expedite your order quickly.

We are globally recognized as the emerging leader of high-quality, nickel alloy fasteners and are proud to serve our customers worldwide.

RAYCHIN Lock Nuts meet applicable ASTM, ANSI, ASME, SAE, API, NAS, AN, MS, NACE, ISO, DIN, and KS standards.

A locknut is a special type of nut that resists loosening from vibrations and torque. One of the most common styles is a prevailing torque locknut. This kind of locknut has a prevailing torque feature which deforms elastically, preventing it from freely spinning like a standard nut.

The two most common and reliable forms of prevailing torque locknuts are the flexloc style and the polymer insert lock nut. A flexloc nut is all-metal in composition with a segmented collar that creates six “locking fingers,” that act as a spring. Polymer insert lock nuts are often referred to as nylon insert locknuts, although various high performance polymers can be used for the screw threads to “bite into.” Both flexlock and polymer insert locknuts are available in both hexagonal and 12 point configurations.