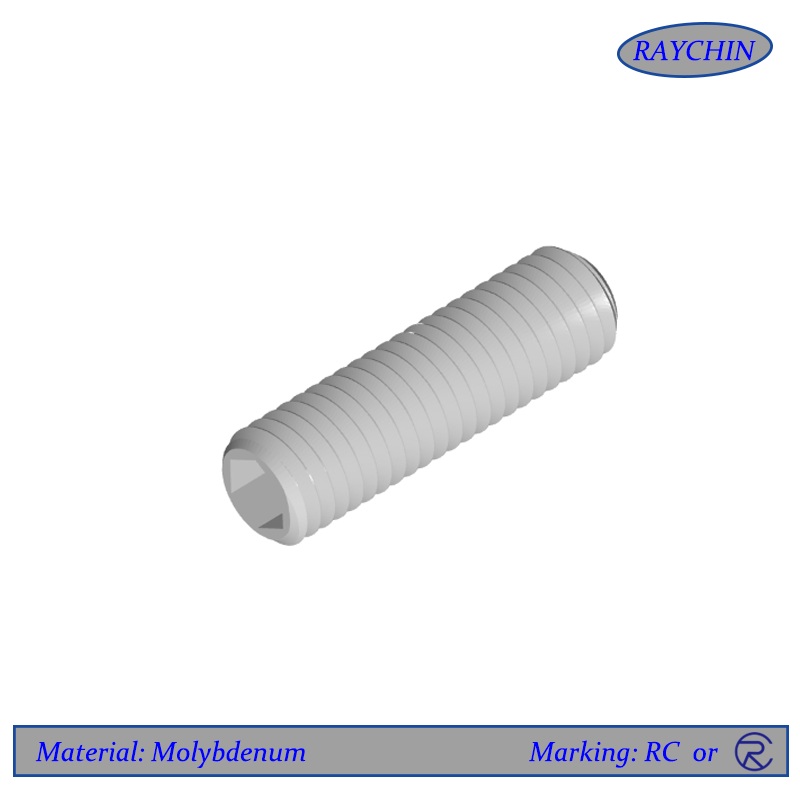

Molybdenum Set Screws

Molybdenum Set Screws

Molybdenum set screws possess a very high melting point of 2620°C, a low coefficient of thermal expansion and a high level of thermal conductivity. Because molybdenum screws have the ability to withstand extremely high temperatures without changing shape, expanding or softening significantly, they are ideal for high strength / high temperature applications that are shielded from oxygen. Exposing molybdenum set screws to oxygen above 600°C will cause them to readily oxidize.

As a result, molybdenum set screws find their way into high temperature vacuum furnaces, glass production, military and space applications where oxygen is not present.

When extreme high temperature stability & strength are required

· Maintains strength at elevated temperatures

· Low distortion at high temperature

· Molybdenum must be used in vacuum or inert gas at high temperatures

· Common molybdenum grades and specifications

· Molybdenum set screw features and benefits

· Molybdenum datasheet

Resources: Molybdenum Torque Spec

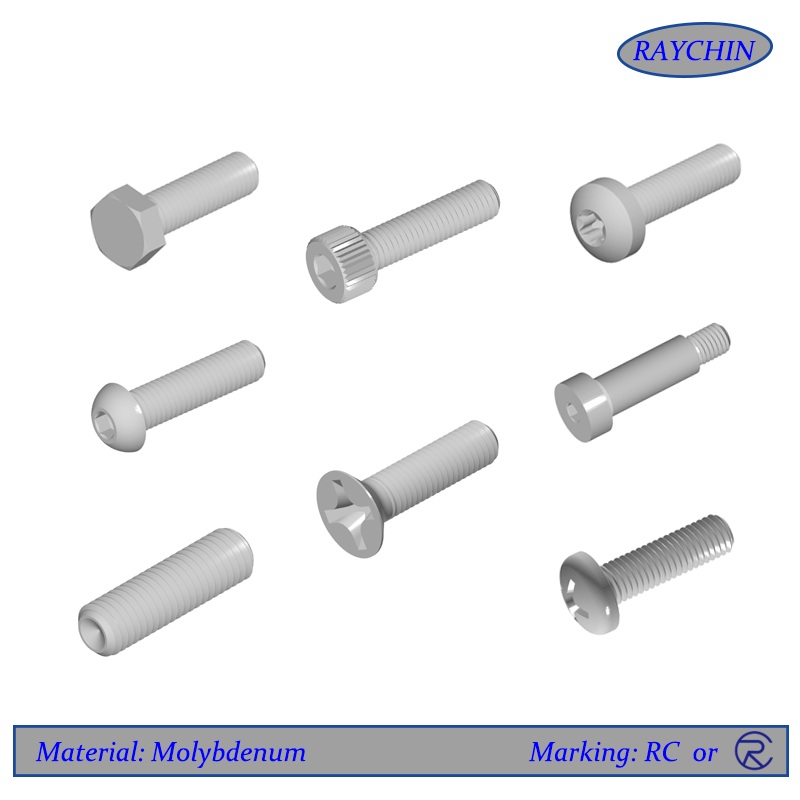

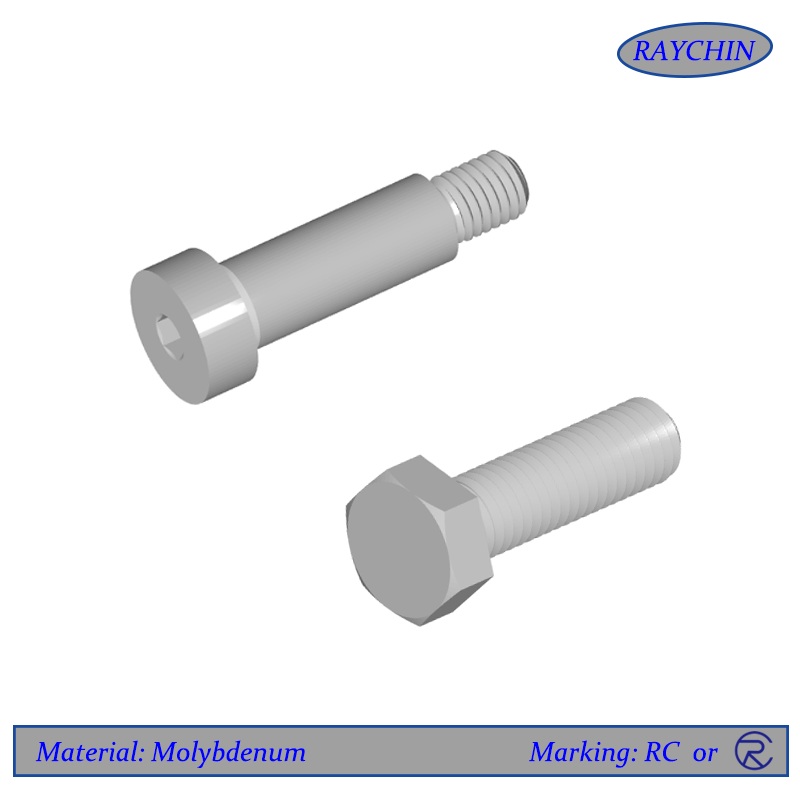

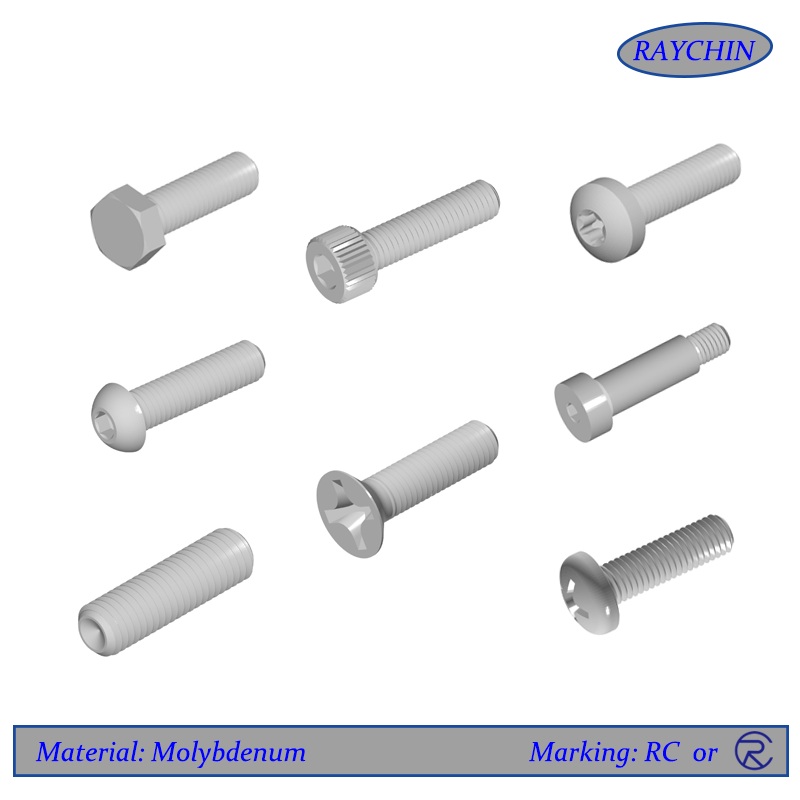

Screw Types: Button Head Cap Screws, Flat Head Screws, Hex Cap Screws, Pan Head Screws, Set Screws, Socket Head Cap Screws, Tamper Resistant Security Screws,

Molybdenum Set Screw Features & Benefits

Molybdenum set screws are unique in that they have no screw head, meaning that they have no protruding part past the threaded shaft. They are thread only and are available with a socket or slotted driver insert at one end. Set screws are used to secure an object within or against another object. Typically they secure a rotating part such as a gear or shaft. Molybdenum set screws are driven through a threaded hole in the rotating part until it is tight against the inner object, preventing from moving relative to the outer object. Set screws are available with various points depending on the application.

Cup Point

This is the most commonly used set screw and is identified by a cup-shaped indentation on one end. Molybdenum cup points are typically used for a quick, semi-permanent or permanent applications where it is acceptable to cut the cup point edge of the screw.

Cone Point

A cone point is easily identifiable by its sharp cone-shaped point – just like an ice cream cone. Molybdenum cone point set screws deliver the strongest clamping force due to the deep penetration of the point. As a result they are used for permanent assembly.

Flat Point

The cheapest and simplest of the set screw point styles, this screw has a flat surface on the bottom of the screw. This type is used when you need the ability to frequently change parts and require minimal shaft deformation.

Common Molybdenum Screw Grades and Specs

Molybdenum (Commercially Pure)

Because of its high melting point of 2620C and its good strength, pure molybdenum finds it niche in high temperature vacuum or inert environments without oxygen.

Molybdenum Specifications: ASTM B386, ASTM B387, Type 361

Molybdenum(cp) | Mo |

Typical% | 99.95 |

TZM - Titanium / Zirconium / Molybdenum Alloy

This alloyed version of molybdenum provides enhanced strenght at elevated temperatures and is excellent for support structures in vacuum furnaces or other high temperatuer and oxygen free environments.

TZM Specifications: UNS R03630, ASTM B384, ASTM B385, ASTM B386, ASTM B387

Moly TZM Alloy | Mo | Ti | Zr |

Typical% | Bal | 10.5 | 0.08 |