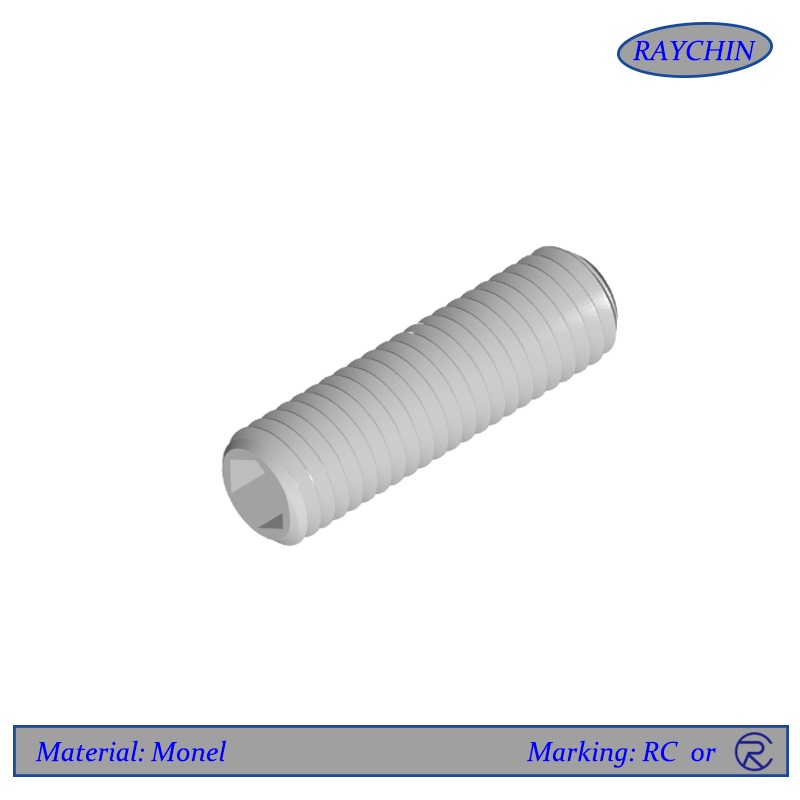

Monel Set Screws

Monel Set Screws

Monel® set screws, like Monel 400 and K500, are made from a nickel-copper alloy and exhibit high strength, toughness and good corrosion resistance over a wide temperature range. An outstanding characteristic of Monel screws is that they offer exceptional resistance to hydrofluoric acid, a particularly tough acid to deal with, in all concentrations up to the boiling point. For hydrofluoric acid applications Monel set screws are perhaps the most resistant of all commonly used specialty alloys.

Monel alloy 400 & K500 set screws also exhibit excellent corrosion resistance in marine applications and have reasonable corrosion resistance to sulfuric and hydrochloric acids under reducing conditions.

Because of these characteristics, Monel set screws are often found in marine and chemical processing applications.

A Ni-Cu alloy with high strength and good corrosion resistance

· Excellent resistance to hydrofluoric acid

· Excellent resistance to sea water for marine applications

· High strength metal with good toughness at high temperatures

· In-depth information on grades 400 and K500

· Datasheets available for Monel 400 and Monel K500

· Monel set screw features and benefits

The most common grades of Monel nickel alloy screws are Monel 400 and Monel K500 . Gain more insight on these two grades by accessing our Monel 400 and K500 overviews or by contacting our engineering experts.

Resources: Monel Torque Spec, Flange Dimensions, Flange Bolting Chart, Monel 400, Monel K500

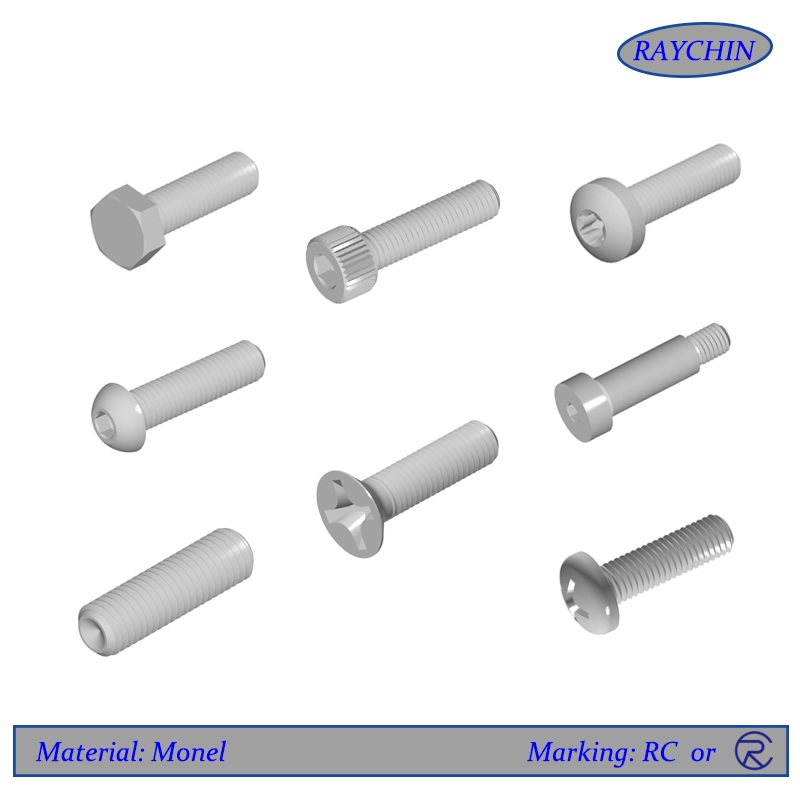

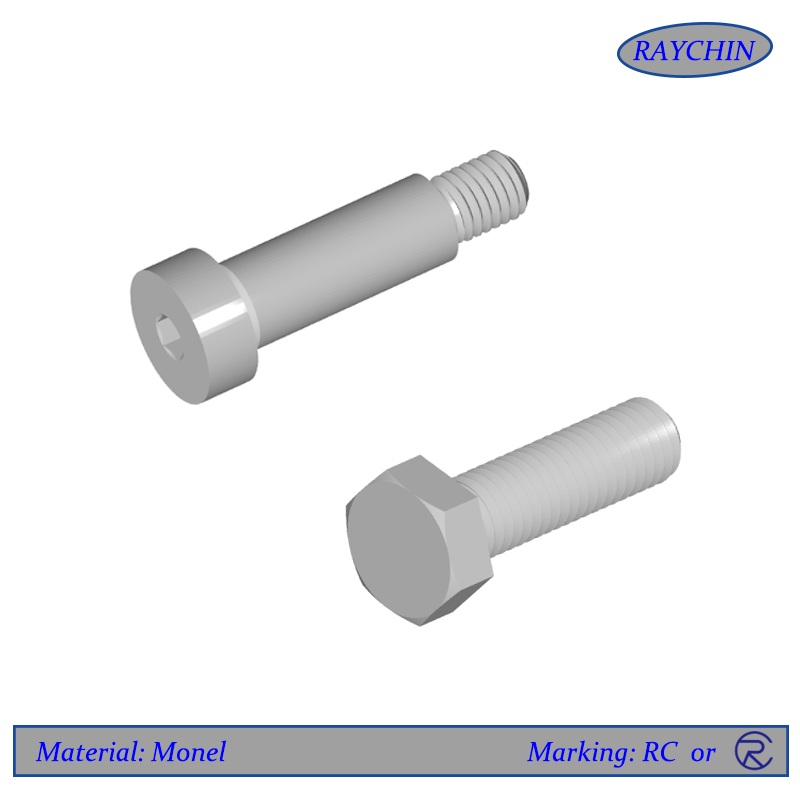

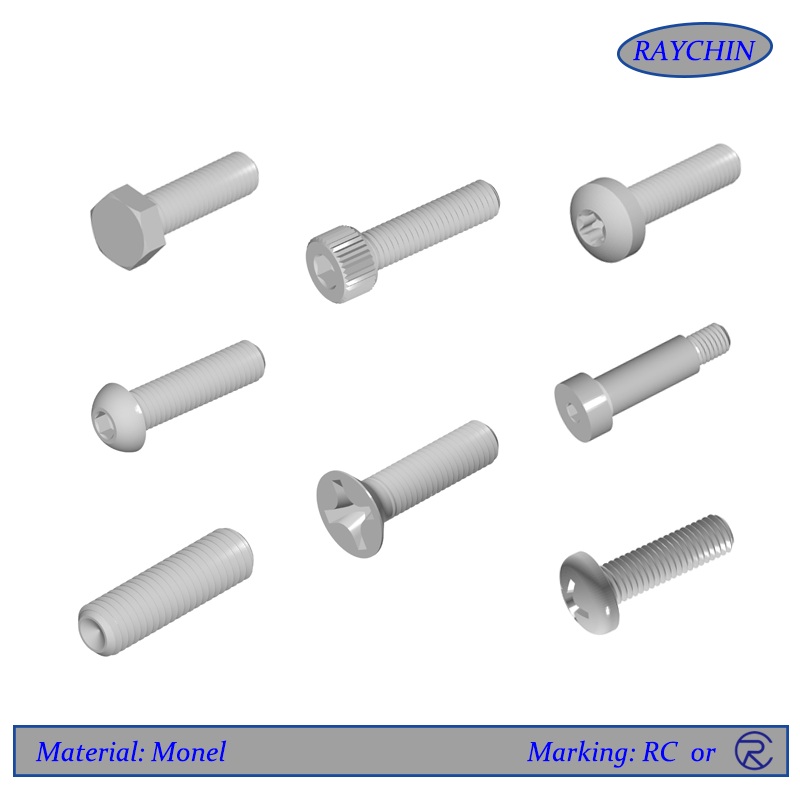

Screw Types: 12 Point Screws, Button Head Cap Screws, Flat Head Screws, Hex Cap Screws, Pan Head Screws, Set Screws, Socket Head Cap Screws, Tamper Resistant Security Screws, Torx Screws

Monel Set Screw Features & Benefits

Monel set screws are unique in that they have no screw head, meaning that they have no protruding part past the threaded shaft. They are thread only and are available with a socket or slotted driver insert at one end. Set screws are used to secure an object within or against another object. Typically they secure a rotating part such as a gear or shaft. Monel set screws are driven through a threaded hole in the rotating part until it is tight against the inner object, preventing from moving relative to the outer object. Set screws are available with various points depending on the application.

Cup Point

This is the most commonly used set screw and is identified by a cup-shaped indentation on one end. Monel cup points are typically used for a quick, semi-permanent or permanent applications where it is acceptable to cut the cup point edge of the screw.

Cone Point

A cone point is easily identifiable by its sharp cone-shaped point – just like an ice cream cone. Monel cone point set screws deliver the strongest clamping force due to the deep penetration of the point. As a result they are used for permanent assembly.

Flat Point

The cheapest and simplest of the set screw point styles, this screw has a flat surface on the bottom of the screw. This type is used when you need the ability to frequently change parts and require minimal shaft deformation.

Common Grades of Monel Screws

Monel 400

Monel 400, UNS N04400 (QQ-N-281), is a nickel-copper alloy with high strength and excellent corrosion resistance in a range of media including sea water, hydrofluoric acid, sulfuric acid, and alkalies. Monel 400 is commonly in marine engineering, chemical and hydrocarbon processing applications.

Monel 400 Specifications: BS3075NA13 (Wire), BS3076NA13 (Bar), ASTM B 164 (Rod, Bar, and Wire), ASTM B 564 (Forgings), ASME SB 164 (Rod, Bar, and Wire), ASME SB 564 (Forgings), AECMA PrEN 2305 (Wire for Rivets), SAE AMS 4675 (Bars and Forgings), SAE AMS 4730 (Wire), SAE AMS 4731 (Wire and Ribbon), DIN 17752 (Rod and Bar), DIN 17753 (Wire), DIN 17754 (Forgings), VdTÜV 263 (Sheet, Plate, Bar, and Tubing), QQ-N-281 (Plate, Sheet, Strip, Bar, Rod, Wire, and Forgings), Werkstoff 2.4360, ASTM F467 (Nuts), ASTM F468 (Bolts, Screws, Studs)

Monel 400 | Ni+Co | Cu | Fe | Mn | Si | C | S |

Min % | 63 | 28.0 | - | - | - | - | - |

Max % | - | 34.00 | 2.50 | 2.00 | 0.50 | 0.30 | 0.024 |

Monel K500

Monel K500, UNS N05500 (QQ-N-286), is a precipitation-hardenable nickel-copper alloy that combines the corrosion resistance of Monel alloy 400 with greater strength (over 2x as strong) and hardness. It also has low permeability and is nonmagnetic to temperatures as low as -150°F (-101°C).

Monel K500 Specifications: BS3075NA18 (Wire), BS3076NA18 (Rod and Bar), ASTM B 865 (Rod and Bar), DIN 17752 (Rod and Bar), DIN 17753 (Wire), DIN 17754 (Forgings), QQ-N-286 (Rod, Bar, Wire, and Forgings), SAE AMS 4676 (Rod and Bar), ASME Code Case 1192 (Rod and Bar), ISO 9723 (Bar), ISO 9724 (Wire), ISO 9725 (Forgings), Werkstoff 2.4375, ASTM F467 (Nuts), ASTM F468 (Bolts, Screws, Studs)

Monel K500 | Ni+Co | Cu | Fe | Mn | Si | C | S | Al | Ti |

Min % | 63 | 27.0 | - | - | - | - | - | 2.30 | 0.35 |

Max % | - | 33.00 | 2.00 | 1.50 | 0.50 | 0.25 | 0.010 | 3.15 | 0.85 |

MONEL 400 - Tensile Data

Temperature (°F) | Ultimate Tensile (ksi) | Yield Strength at 0.2% Offset (ksi) | Elongation % |

Room Temp. | 83 | 32 | 45 |

200 | 79 | 30 | 43 |

400 | 77 | 27 | 42 |

600 | 80 | 27 | 46 |

800 | 68 | 26 | 48 |

1000 | 54 | 24 | 40 |

MONEL K500 - Tensile Data

Temperature (°F) | Ultimate Tensile (ksi) | Yield Strength at 0.2% Offset (ksi) | Elongation % |

Room Temp. | 160 | 110 | 45 |

200 | 150 | 108 | 47 |

400 | 147 | 105 | 48 |

600 | 142 | 103 | 49 |

800 | 125 | 102 | 19 |

1000 | 95 | 90 | 8 |

PRESSURE - TEMPERATURE RATINGS FOR MONEL 400

Nominal Designation | Forgings | Castings | Plates |

67Ni 30Cu |

| B564Gr. N04400(1) | ... |

| B127Gr. N04400(1) |

Working Pressures by Classes psig |

Temp F | 150 | 300 | 400 | 600 | 900 | 1500 | 2500 |

20 to 100 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

200 | 200 | 525 | 700 | 1050 | 1575 | 2630 | 4380 |

300 | 190 | 490 | 655 | 980 | 1470 | 2450 | 4080 |

400 | 180 | 475 | 530 | 945 | 1420 | 2365 | 3340 |

500 | 170 | 475 | 630 | 945 | 1420 | 2365 | 3940 |

600 | 140 | 475 | 630 | 945 | 1420 | 2365 | 3340 |

650 | 125 | 475 | 630 | 945 | 1420 | 2365 | 3940 |

700 | 110 | 470 | 525 | 940 | 1410 | 2350 | 3920 |

750 | 95 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

800 | 80 | 460 | 610 | 915 | 1375 | 2290 | 3820 |

850 | 65 | 375 | 505 | 755 | 1130 | 1885 | 3145 |

900 | 50 | 275 | 365 | 550 | 825 | 1370 | 2285 |