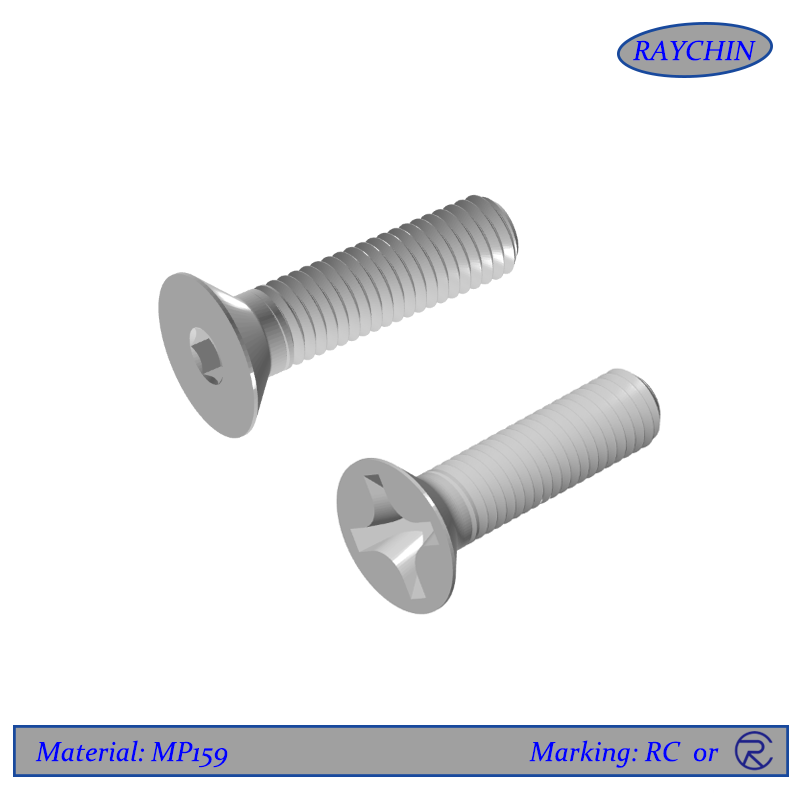

MP159 Flat Head Screws

Brand RAYCHIN

Product origin China

Delivery time 5-35 DAYS

As aerospace engineering advances, so must the materials to meet the technological requirements of this industry. Screws made from MP159 have been developed to provide a solution to high temperature, high strength components. MP159 flat head screws offer strength capabilities similar to other Cobalt Alloys (MP35N) but can be used at much higher temperatures - up to 1100°F, compared to MP35N’s usable limit of 800F. In addition, MP159 flat head screws can be used beyond 1100°F in short term situations.

MP159 Flat Head Screws

As aerospace engineering advances, so must the materials to meet the technological requirements of this industry. Screws made from MP159 have been developed to provide a solution to high temperature, high strength components. MP159 flat head screws offer strength capabilities similar to other Cobalt Alloys (MP35N) but can be used at much higher temperatures - up to 1100°F, compared to MP35N’s usable limit of 800F. In addition, MP159 flat head screws can be used beyond 1100°F in short term situations.

Ultra-strength combined with extreme temperature capabilities

· Extreme high strength properties up to 275 ksi ultimate tensile.

· Maintains superior strength to 1100°F.

· MP159 chemisty and specification

· Datasheet for MP159

· MP159 flat head screw features & benefits

Key Benefits

· High ultimate tensile strength of 275 ksi and yield strength of 265 ksi (Cold Worked and Age Hardened) combined with excellent ductility and toughness

· Similar corrosion resistance compared to MP35N which is usable in mineral acids, hydrogen sulfide, seawater and salt spray environments.

· Excellent fatigue resistance and creep strength at elevated temperatures

· Excellent resistance to crevice corrosion, stress corrosion cracking and hydrogen embrittlement

Applications

· The aerospace industry relies on MP159 screws for its most advanced gas turbine and jet engines, rocket boosters and jet propulsion systems.

· Power generation and chemical processing utilize MP159 flat head screws for applications that demand high strength at extreme temperatures.

Resources: MP159 Torque Spec

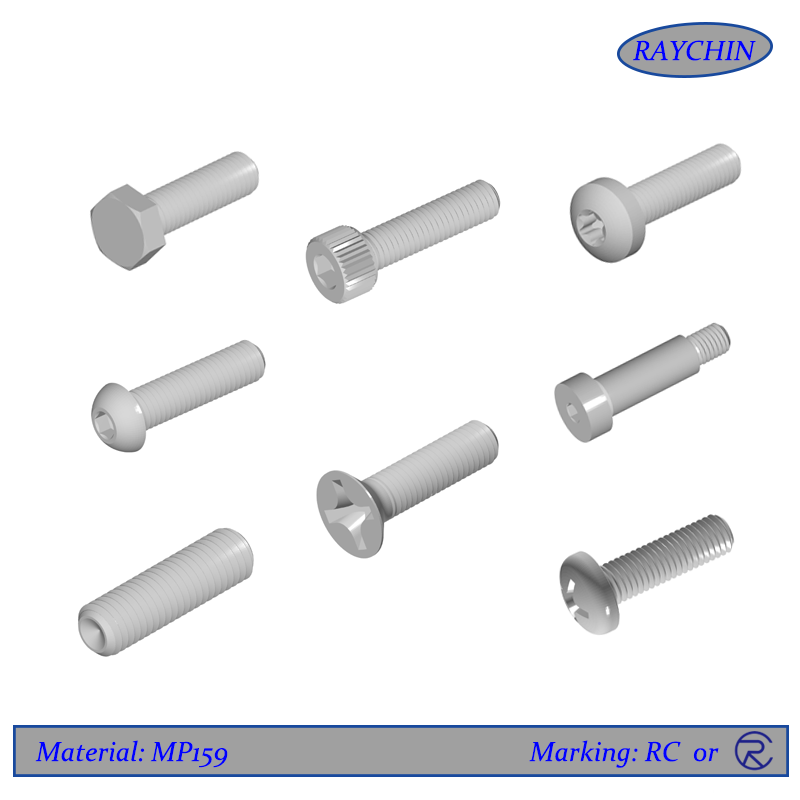

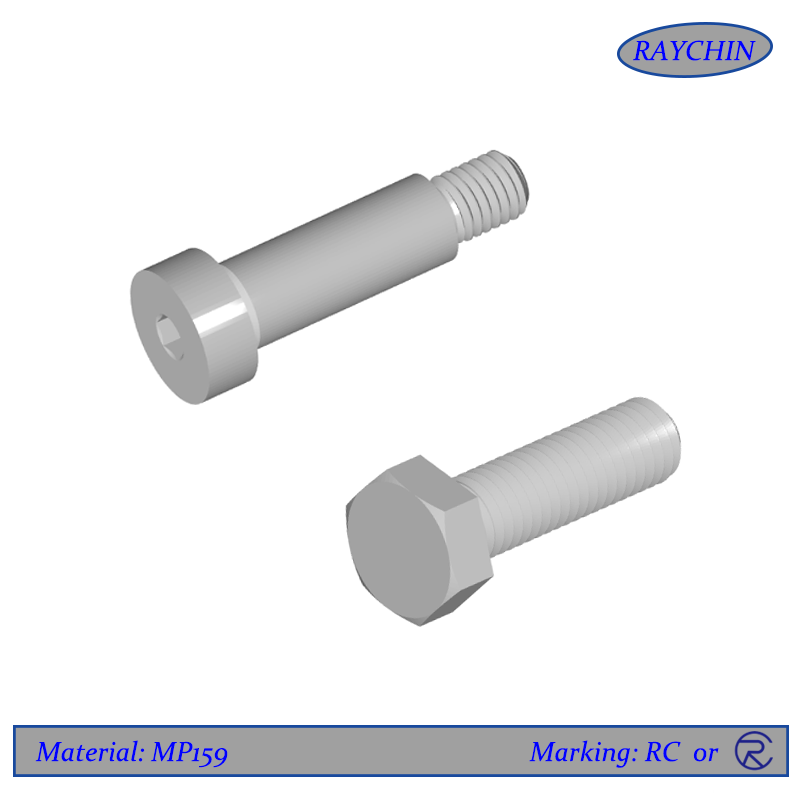

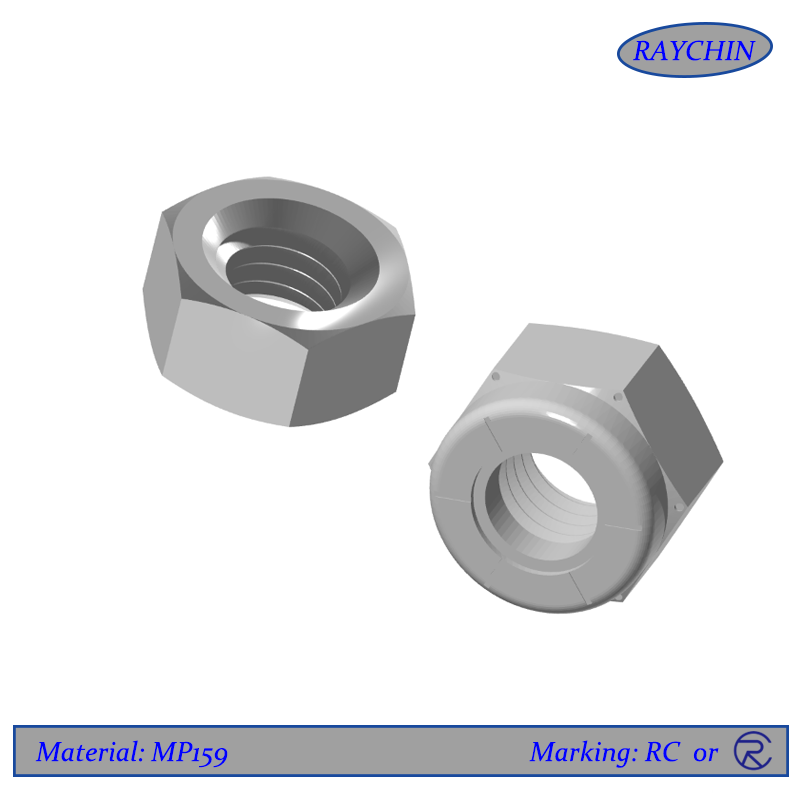

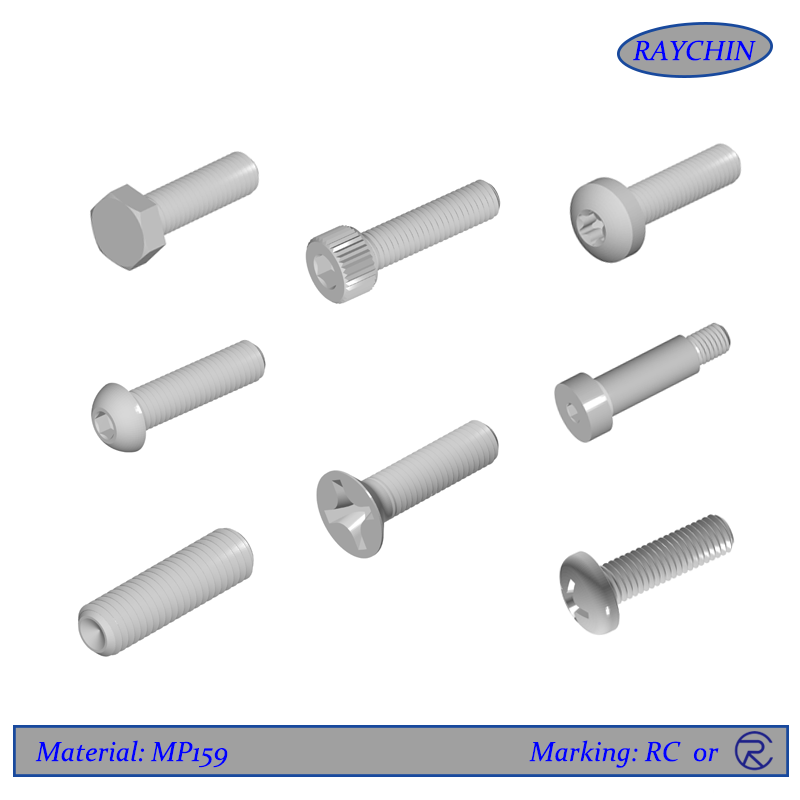

MP159 Screw Types: 12 Point Screws, Button Head Cap Screws, Flat Head Screws, Hex Cap Screws, Hex Cap Screws, Set Screws, Socket Head Cap Screws, Tamper Resistant Security Screws

MP159 Flat Head Screw Features and Benefits

MP159 flat head screws are characterized by having a head with a top flat surface (which can feature either a slotted, phillips or allen driver) and bottom that is cone shaped or countersunk. With this design, the head of the screw can align flush or below the surrounding surface having obvious benefits.

MP159 Slotted vs. Phillips Driver

Slotted Head Advantages | Phillips Head Advantages |

· Slotted head screws tend to strip less than Philips, especially in harsh environments · Slotted heads are typically better in applications where it's going to be unscrewed and re-done periodically, as the head tends to wear less. · In dirty environments, a flat head is much easier to clean out | · Phillips head offers a much stronger joint since it can tolerate more torque. |

Countersink Angle

For most MP159 flat head screw designs the angle of countersink is usually 82° for UNC and UNF applications however other angles ranging from 60° -120° could be specified.

Thread Type | Normal Flat Head Countersink Angle |

UNC / UNF | 82° |

Aerospace | 100° |

ISO Metric / Imperial | 90° |

MP159 Chemistry and Specifications

MP159N Specifications: UNS R30159

MP159 | Co | Ni | Cr | Fe | Mo | Ti | Nb | Al |

Typical% | 35.7 | 25.5 | 19 | 9 | 7 | 3 | 0.6 | 0.2 |

MP159 High Strength Data

Cold Worked, 48% +1225eF (663eC)/4 hrs/AC | |

UTSksi(MPa) | 275(1895) |

Yield strength at 0.2% ksi (MPa) | 265(1825) |

% Elogation | 8 |

%RA | 35 |

Shear strength ksi (MPa) Per MIL- STD-1312 | 138(951) |