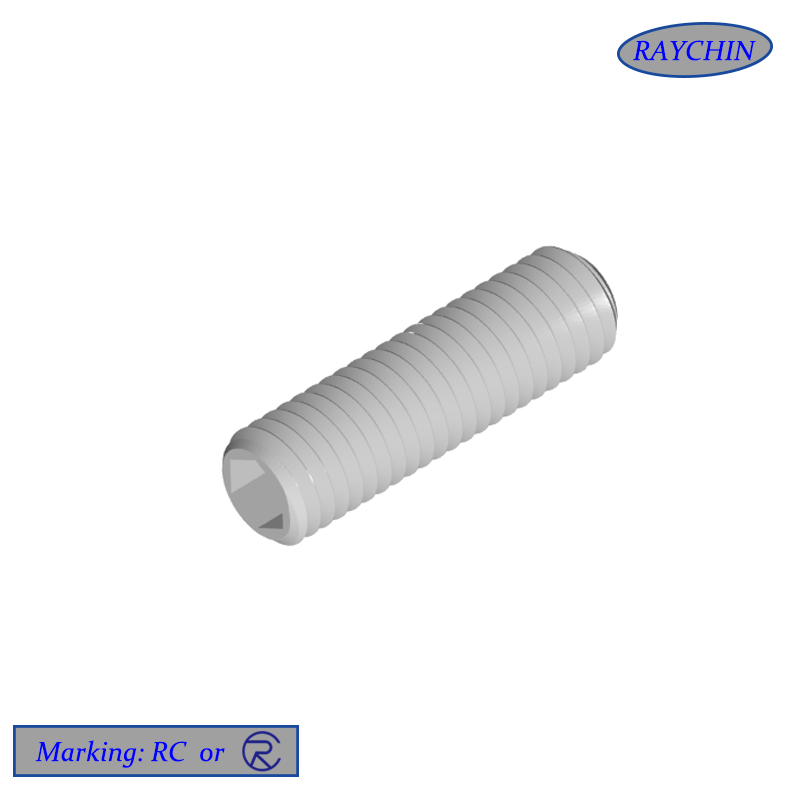

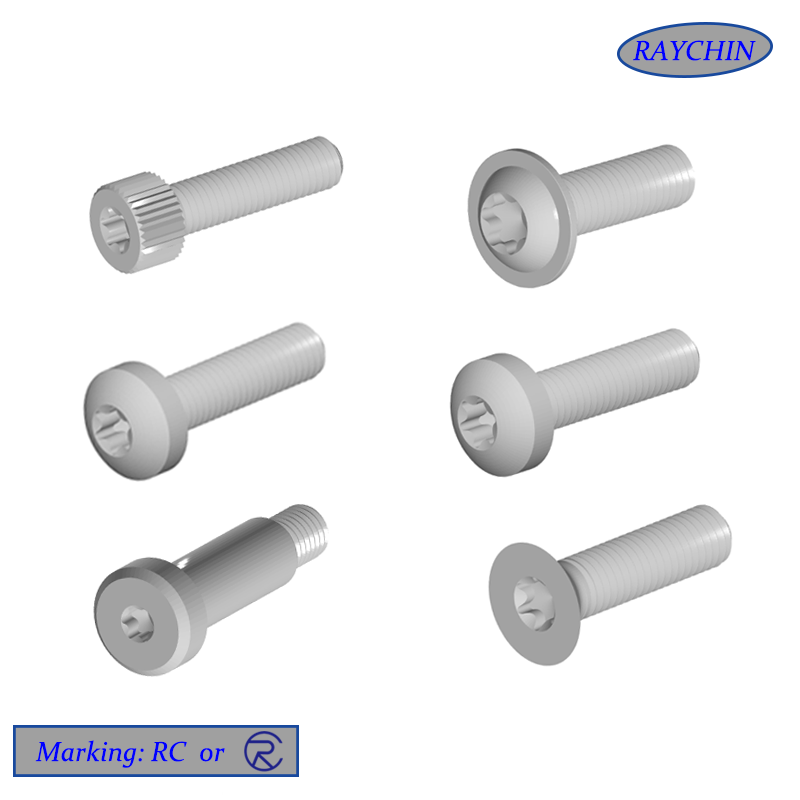

Set screws are unique in that they have no screw head, meaning that they have no protruding part past the threaded shaft: they are thread only with a socket or slotted driver insert at one end. Set screws are used to secure an object within or against another object. Typically they secure a rotating part such as a gear or shaft. Set screws are driven through a threaded hole in the rotating part until it is tight against the inner object, preventing from moving relative to the outer object. Set screws are available with with these points:

Cup Point Cone Point

Flat Point |

Set Screws

Brand RAYCHIN

Product origin China

Delivery time 5-35 DAYS

Set Screws

RAYCHIN is a manufacturer and worldwide supplier of standard & custom fasteners(Set Screws) including those manufactured from the following materials: Hastelloy® C-276, Hastelloy® C-22, Hastelloy® B-2, Hastelloy® G-30, Monel® 400, Monel® K-500, Inconel® 600, Inconel® 625, Inconel® 718, Incoloy® A-286, Titanium Grade 2, Titanium Grade 5, Titanium Grade 7, Nickel 200, Nickel 200, Aluminum, Molybdenum, Nimonic, Nitronic, Tantalum, Tungsten, Waspaloy, Zirconium, Duplex S31803, Duplex S32205 and Super Duplex S32750, etc.

Set Screws

| Set Screw Sizes • #00 - 6" • M1.2 - M150 Availability • Fine and course threads. • Socket (hex) drive and slotted drives are both available. | Set Screw Specifications • ASME B18.3, DIN 913 / ISO 4026 • DIN 913 / ISO 4026 • DIN 914 / ISO 4027 • DIN 915 / ISO 4028 • DIN 916 / ISO 4029 |

RAYCHIN Set Screws are manufactured by the cold heading and hot forming technologies We offer fasteners in both USCS/Imperial and metric sizes.

RAYCHIN’s advanced and comprehensive range of capabilities include engineering, R&D, prototyping, custom manufacturing, precision processing and testing. All RAYCHIN materials are sourced from the most reputable and exacting foundries in the world. We maintain a multi-million-dollar inventory of fasteners in our product warehouse, which enables RAYCHIN to select, package and expedite your order quickly.

We are globally recognized as the emerging leader of high-quality, nickel alloy fasteners and are proud to serve our customers worldwide.

RAYCHIN Set Screws meet applicable ASTM, ANSI, ASME, SAE, API, NAS, AN, MS, NACE, ISO, DIN, and KS standards.