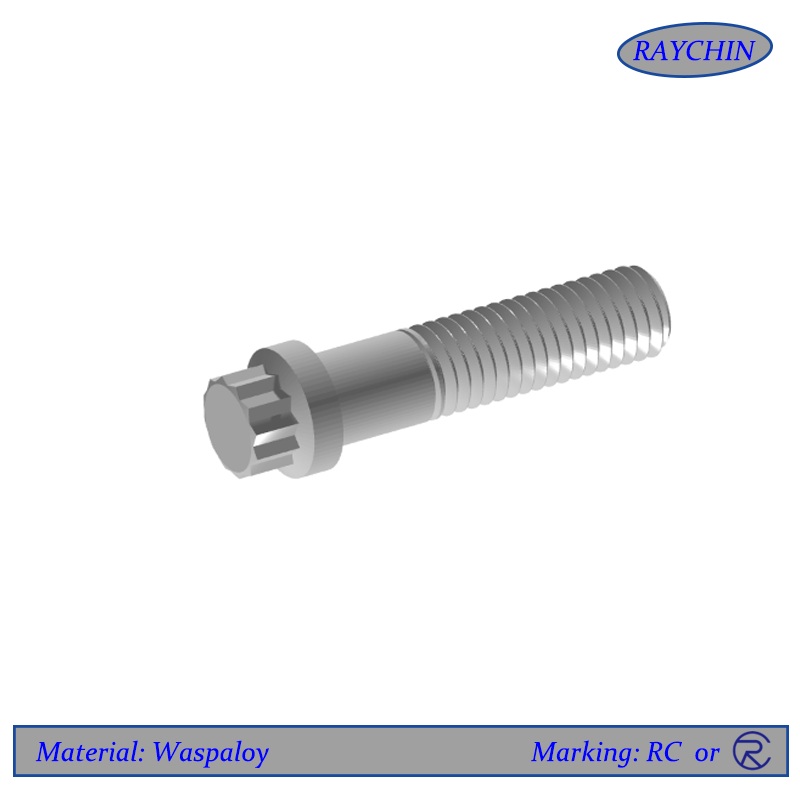

Waspaloy 12 Point Screws

Brand RAYCHIN

Product origin China

Delivery time 5-35 DAYS

Waspaloy 12 point screws are known for their superb high strength at elevated temperatures. Waspaloy is a high performance nickel alloy combined with cobalt, chrome and molybdenum to create it’s unique combination of strength and high temperature stability.

Similar to that of Inconel 718 screws, Waspaloy screws exceed the strength and stability of Inconel 718 at elevated temperatures beyond 1400°F. In addition, the oxidation resistance of Waspaloy 12 point screws make it an ideal materials for high temperature applications like gas turbines engines, and a variety of other aerospace components.

Waspaloy 12 Point Screws

Waspaloy 12 point screws are known for their superb high strength at elevated temperatures. Waspaloy is a high performance nickel alloy combined with cobalt, chrome and molybdenum to create it’s unique combination of strength and high temperature stability.

Similar to that of Inconel 718 screws, Waspaloy screws exceed the strength and stability of Inconel 718 at elevated temperatures beyond 1400°F. In addition, the oxidation resistance of Waspaloy 12 point screws make it an ideal materials for high temperature applications like gas turbines engines, and a variety of other aerospace components.

An age hardened super alloy with exceptional strength at high temperatures

· Extreme high temperature strength

· Service temperatures up to 1600°F (870°C)

· Very oxidation resistant

· Waspaloy chemistry & specifications

· Datasheet for Waspaloy

· Waspaloy 12 point screw features and benefits

Resources: Waspaloy Torque Specs

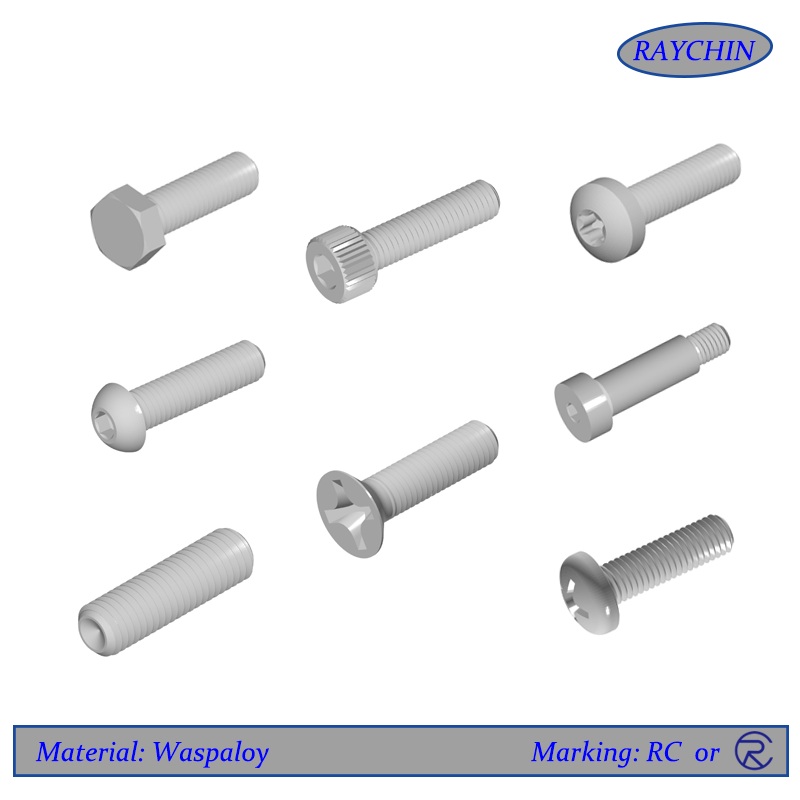

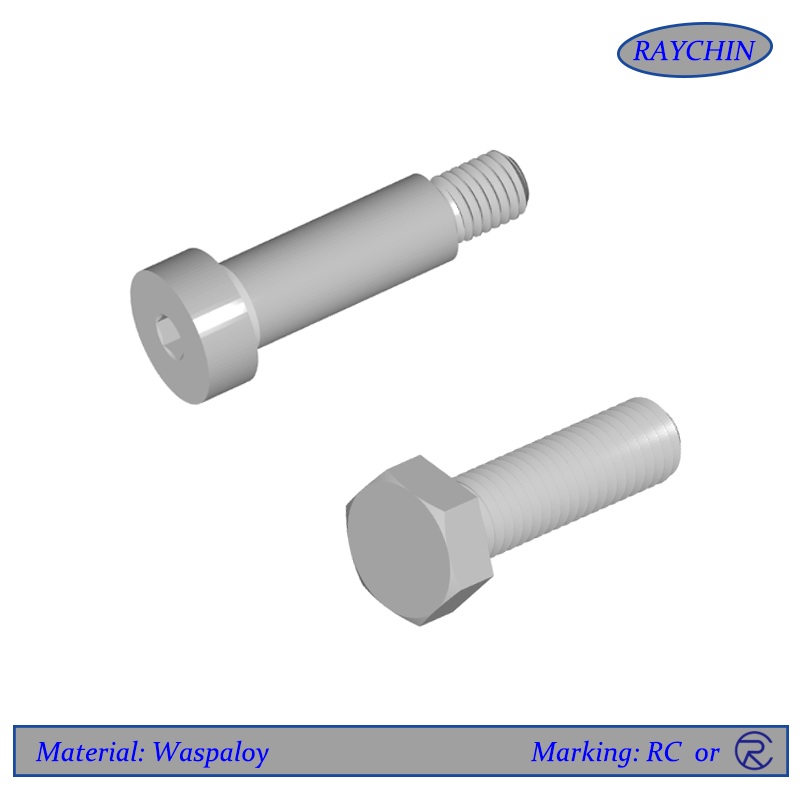

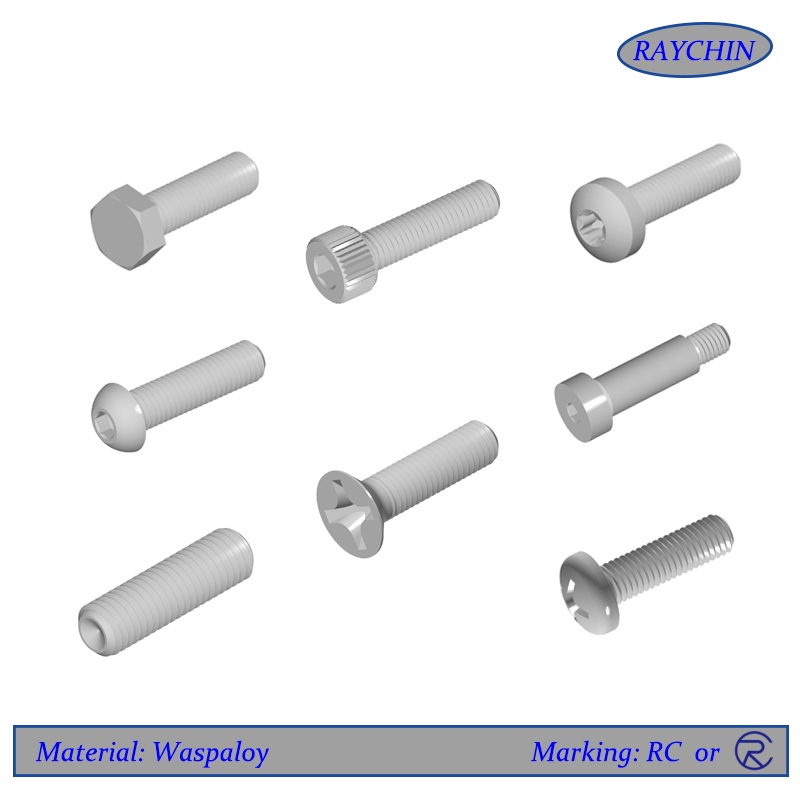

Screw Types: 12 Point Screws, Button Head Cap Screws, Flat Head Screws, Hex Head Cap Screws, Pan Head Screws, Set Screws, Socket Head Cap Screws, Tamper Resistant Security Screws, Torx Screws

Waspaloy 12-Point Screw Features & Benefits

The driver of a Waspaloy 12-point screw uses two overlapped hexagon shapes, creating 12-points and a flanged underside. These are also referred to as ferry cap screws or 12 point flange screws. The advantages of this head style include:

· Higher torque capability compared to a socket head cap screw

· Lack of recess to trap fluid or debris.

· As the heads are generally smaller than a hex, Waspaloy 12-point screws are often used situations where installation space is tight and saving weight is critical.

The overall disadvantage is the extra cost involved in forming the heads.

The Controversy of 6 vs. 12 point Bolts

There is much debate over which bolt is better. Some say that the more points a nut or bolt has – such as a 12-point bolt - the less chance you have to round it off. And that the additional contact points of a 12 point screw give you more surface to apply load. While the jury is out as to the accuracy of this, it’s the application that should dictate whether the benefits of a 12 point screw out weight the additional costs of making them.

Waspaloy (2.4654) Chemistry & Specifications

Waspaloy (2.4654) is a solution annealed and age hardended alloy which provides its high strength properties. There are a few aging varieties however the AMS 5708 is one of the more common.

Waspaloy Specifications: UNS N07001, ASTM B 637, AMS 5708, AMS 5709, EN 2.4654, Werkstoff 2.4654

Waspaloy | Ni | Cr | Co | Mo | Ti | Fe | Al | Mn | Si | Cu | Zr | C | P | S | B |

Min% | - | 18.0 | 12.0 | 3.50 | 2.75 | - | 1.20 | - | - | - | 0.02 | 0.02 | - | - | 0.0 |

Max% | Bal | 21.0 | 15.0 | 5.00 | 3.25 | 2.0 | 1.60 | 1.00 | 0.75 | 0.50 | 0.12 | 0.10 | 0.030 | 0.030 | 0.010 |