An age hardened super alloy with exceptional strength at high temperatures

Extreme high temperature strength

Service temperatures up to 1600°F (870°C)

Very oxidation resistant

Waspaloy chemistry & specifications

Datasheet for Waspaloy

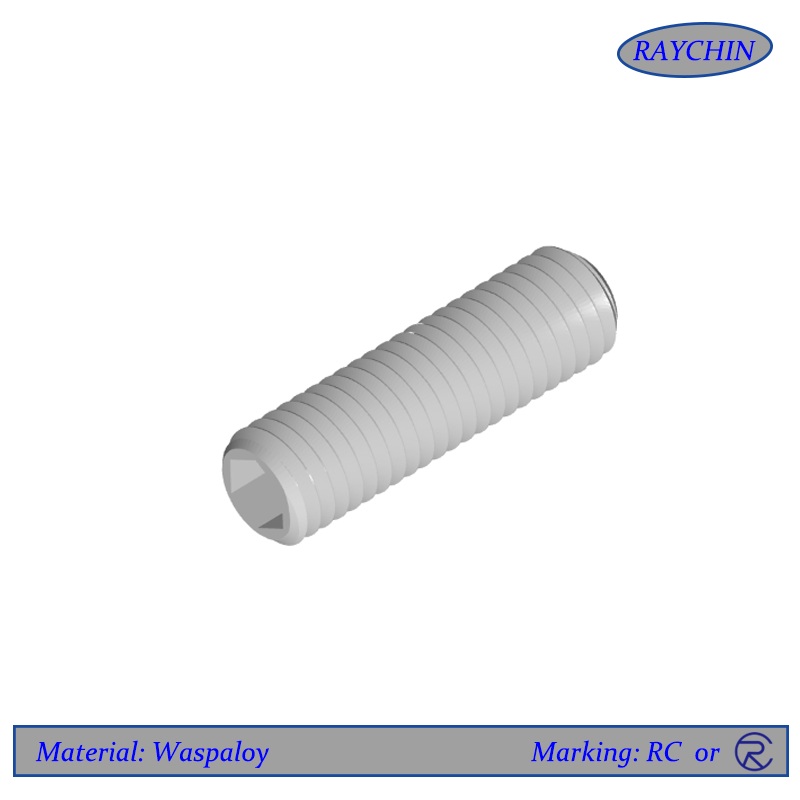

Waspaloy set screw features and benefits

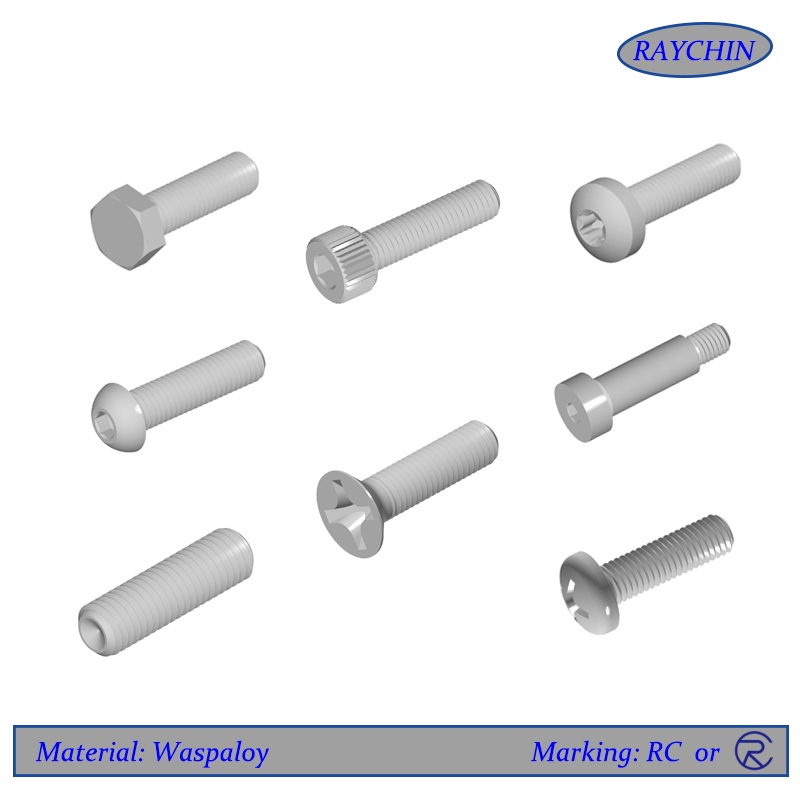

Waspaloy set screws are known for their superb high strength at elevated temperatures. Waspaloy is a high performance nickel alloy combined with cobalt, chrome and molybdenum to create it’s unique combination of strength and high temperature stability.

Similar to that of Inconel 718 screws, Waspaloy set screws exceed the strength and stability of Inconel 718 at elevated temperatures beyond 1400°F. In addition, the oxidation resistance of Waspaloy screws make it an ideal materials for high temperature applications like gas turbines engines, and a variety of other aerospace components.

Resources: Waspaloy Torque Specs

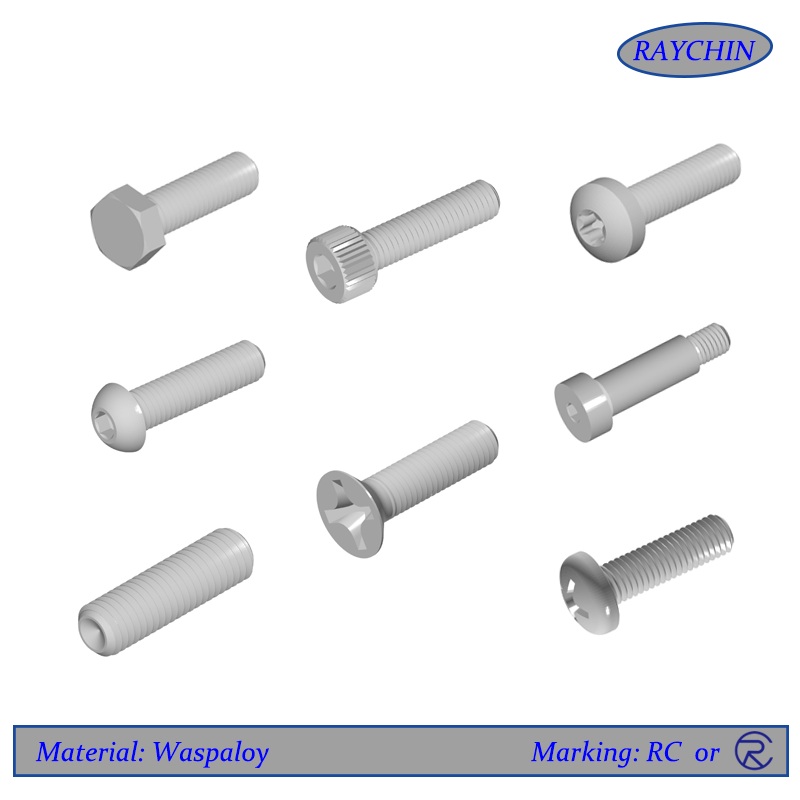

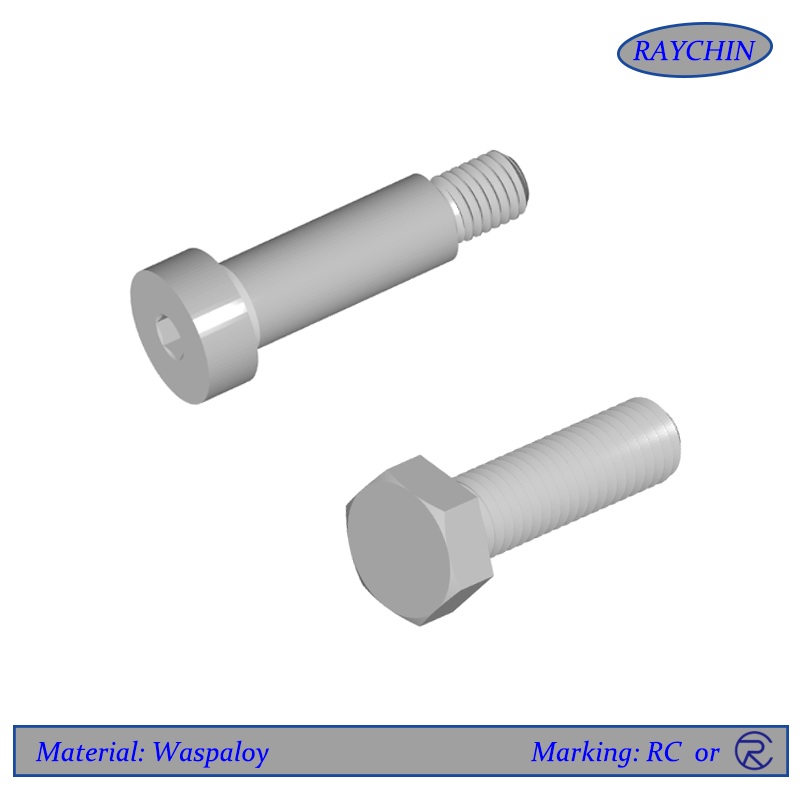

Screw Types: 12 Point Screws, Button Head Cap Screws, Flat Head Screws, Hex Head Cap Screws, Pan Head Screws, Set Screws, Socket Head Cap Screws, Tamper Resistant Security Screws, Torx Screws

Waspaloy Set Screw Features & Benefits

Waspaloy set screws are unique in that they have no screw head, meaning that they have no protruding part past the threaded shaft. They are thread only and are available with a socket or slotted driver insert at one end. Set screws are used to secure an object within or against another object. Typically they secure a rotating part such as a gear or shaft. Waspaloy set screws are driven through a threaded hole in the rotating part until it is tight against the inner object, preventing from moving relative to the outer object. Set screws are available with various points depending on the application.

Cup Point

This is the most commonly used set screw and is identified by a cup-shaped indentation on one end. Waspaloy cup points are typically used for a quick, semi-permanent or permanent applications where it is acceptable to cut the cup point edge of the screw.

Cone Point

A cone point is easily identifiable by its sharp cone-shaped point – just like an ice cream cone. Waspaloy cone point set screws deliver the strongest clamping force due to the deep penetration of the point. As a result they are used for permanent assembly.

Flat Point

Flat Point

The cheapest and simplest of the set screw point styles, this screw has a flat surface on the bottom of the screw. This type is used when you need the ability to frequently change parts and require minimal shaft deformation.

Waspaloy (2.4654) Chemistry & Specifications

Waspaloy (2.4654) is a solution annealed and age hardended alloy which provides its high strength properties. There are a few aging varieties however the AMS 5708 is one of the more common.

Waspaloy Specifications: UNS N07001, ASTM B 637, AMS 5708, AMS 5709, EN 2.4654, Werkstoff 2.4654

Waspaloy | Ni | Cr | Co | Mo | Ti | Fe | Al | Mn | Si | Cu | Zr | C | P | S | B |

Min% | - | 18.0 | 12.0 | 3.50 | 2.75 | - | 1.20 | - | - | - | 0.02 | 0.02 | - | - | 0.0 |

Max% | Bal | 21.0 | 15.0 | 5.00 | 3.25 | 2.0 | 1.60 | 1.00 | 0.75 | 0.50 | 0.12 | 0.10 | 0.030 | 0.030 | 0.010 |