-

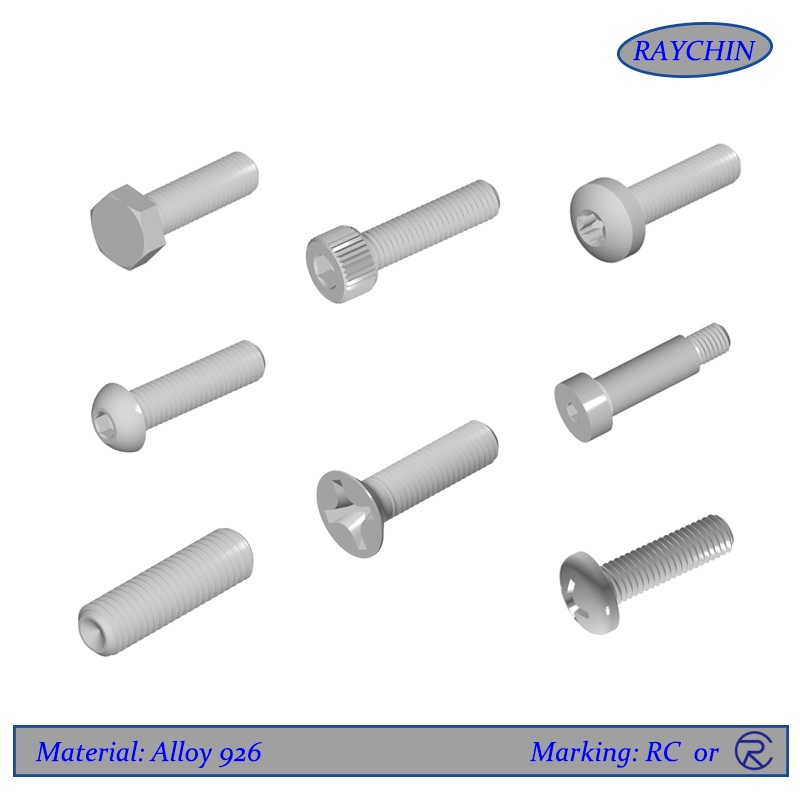

Alloy 926 Fasteners

Alloy 926 (1.4529) screws are the perfect substitute for 316L when higher corrosion resistance is required without additional strength. Alloy 926 fasteners are considered a 6-Moly alloy (6 Mo or 6% Molybdenum) like sister alloys AL6XN and SMO 254. Within the class of stainless steels, these 6 Mo alloys are considered to be very corrosion resistant. Bolts made from Alloy 926 are a super-austenitic molybdenum stainless steel offering corrosion resistance comparable to Super Duplex 2507 but with slightly lower strength and cost. Almost identical in chemistry to 6 Moly alloys AL6XN and SMO 254, Alloy 926 is often chosen for paper plants, desalination and weak acid environements.

Send Email Details

In addition, Alloy 926 fasteners are also similar in composition to 904L, but with increased nitrogen and molybdenum providing Alloy 926 bolts improved general corrosion resistance as well as resistance to pitting and crevice corrosion. Because of Alloy 926 resistance to chloride stress corrosion cracking, it makes 926 fasteners ideal for use in desalination, and pulp and paper plants. This alloy is also good option for diluted sulfuric and phosphorus acid applications. -

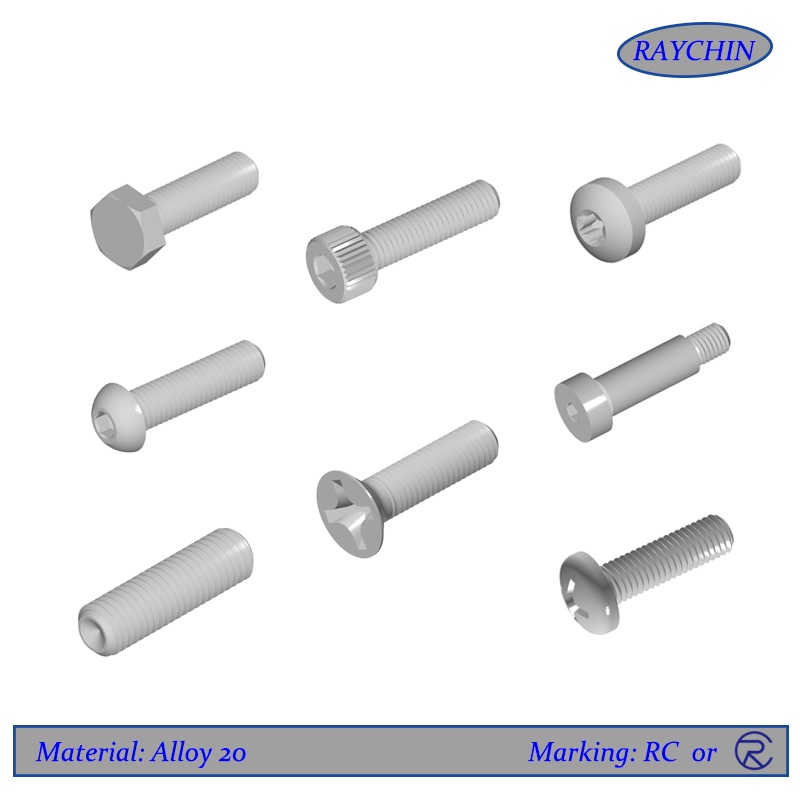

Alloy 20 Fasteners

Alloy 20 fasteners, also known as Carpenter 20 and 20CB-3, offers a combination of nickel, chromium, molybdenum, and copper which provides good general corrosion resistance. Alloy 20 (2.4660) fasteners are best suited for mid-range corrosion use – better than steel alloys but not at the level of high performance nickel based alloys like Hastelloy C276. Alloy 20 is a nickel alloy that was specifically designed to withstand the harsh environment of hot sulfuric acid but also performs well in a variety of other acids. Alloy 20 fasteners are an ideal choice when you don’t need the corrosion resistance power and price-tag of high performance nickel alloys like Hastelloy C276; but you need something that will give you more protection than 316 stainless steel or even a Super Duplex 2507 stainless steel.

Send Email Details -

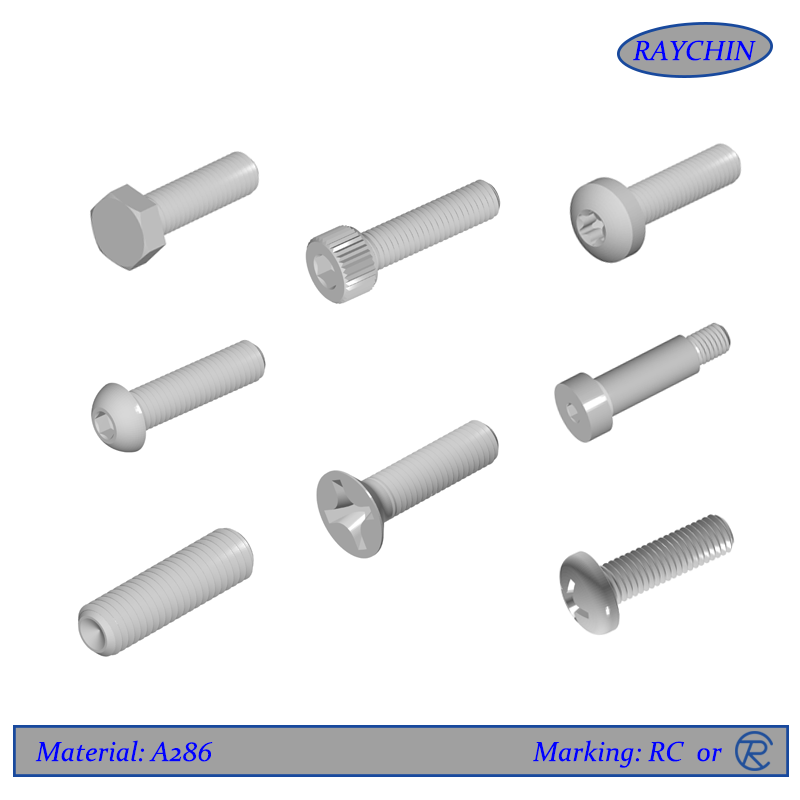

A286 Fasteners

A286 (1.4980) fasteners, also known as Alloy 660 fasteners are stainless steel alloy which contains iron, nickel and chromium. A286 fasteners are known for their high strength, creep resistance and oxidation resistance at elevated temperatures once age hardened. As a result, A286 fasteners provide high levels of strength from room temperature up to about 1300°F (700°C).

Send Email Details

A286 fasteners are also mildly corrosion resistant. While they should not be used for strong acid environments, they provide excellent oxidation resistance up to 1500°F (815°C) in conditions that would typically be found in high temperature exhaust streams. Because A286 fasteners are used in high temperature applications where performance is critical, we can provide fasteners to ASTM A453 Grade 660 in order to ensure accurate standards for tensile and stress rupture properties. -

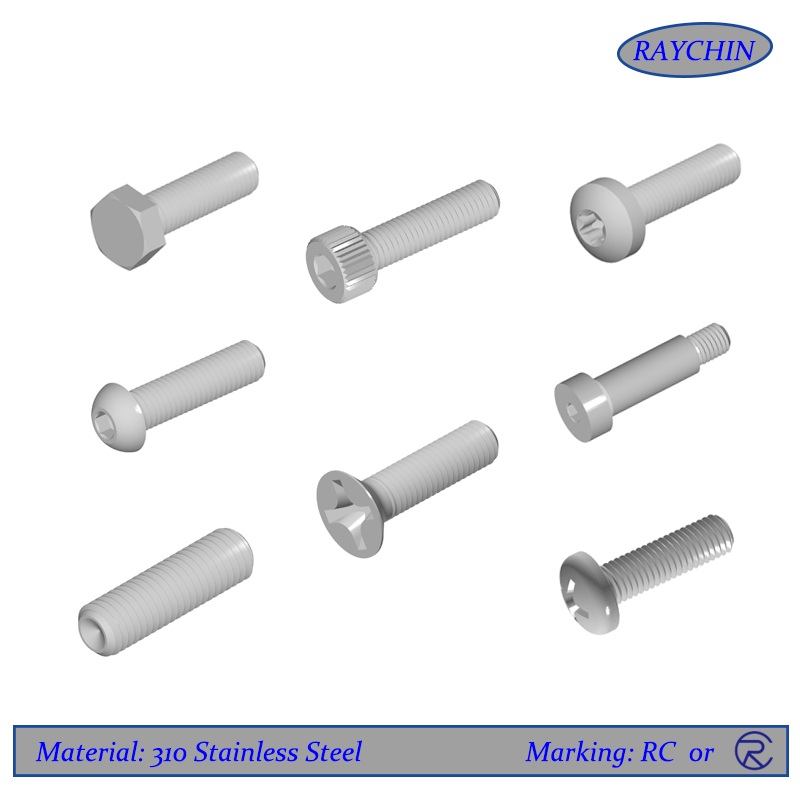

310 Stainless Steel Fasteners

Designed for high temperature applications, 310 stainless steel fasteners provide high temperature oxidation resistance to 2000°F under mild cyclic conditions. An economic alternative to nickel alloys like alloy 330 or Inconel, 310 fasteners provide slightly less strength and temperature resistance – but at a significantly lower price point. Alloy 310 can be used in moderately caburizing, moderately oxidizing, nitriding, cementing and thermal cycling applications when not used at the maximum service temperature. 310SS fasteners also have good resistance to sulfidation and other forms of hot corrosion. Although primarily known for its high temperature properties, 310 stainless steel also provides excellent performance at cryogenic temperatures, with toughness down to -450˚F. Though 310 is ideal for high temperature use, it should not be exposed to the severe thermal shock of repeated liquid quenching or where aqueous corrosive contaminants are present.

Send Email Details -

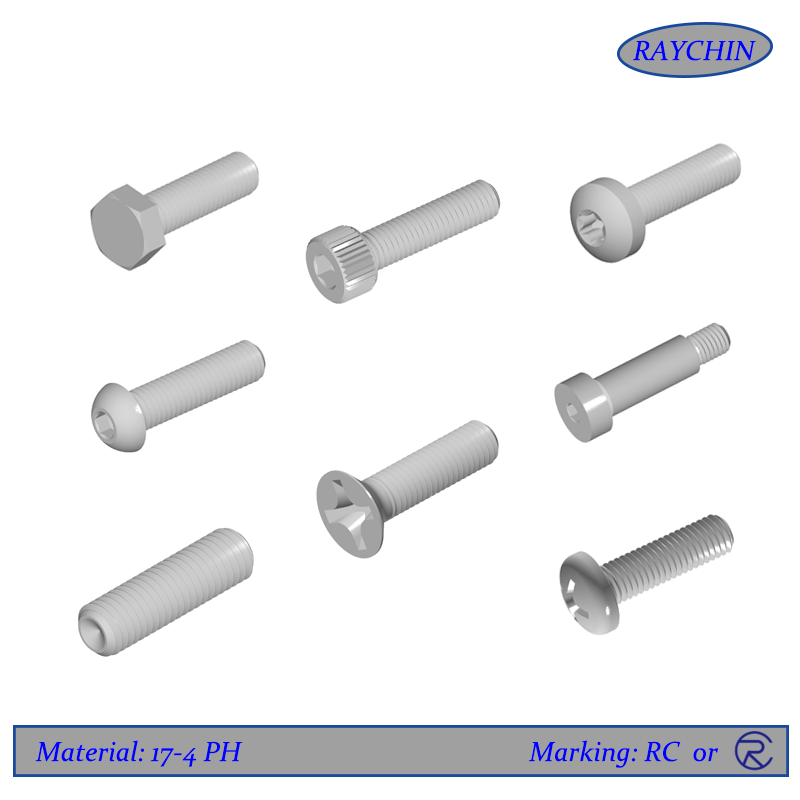

17-4 PH Fasteners

17-4 PH fasteners are made from a precipitation hardened stainless steel most known for its exceptional strength and its ability to maintain its mechanical properties to 600°F. Compared to 316 stainless steel, 17-4 PH fastener's yield strength is up over 4 times greater. When compared to Duplex 2205 fasteners, the yield strength of 17-4 PH can be up to 2-½ times greater.

Send Email Details

RAYCHIN 17-4 fasteners are available in 8 different aged (precipitation hardened) conditions offering a variety of mechanical properties (see below). In addition, we also offer 17-4PH fasteners per ASTM F593 Grade 630 which ensures specific tensile and yield strengths. -

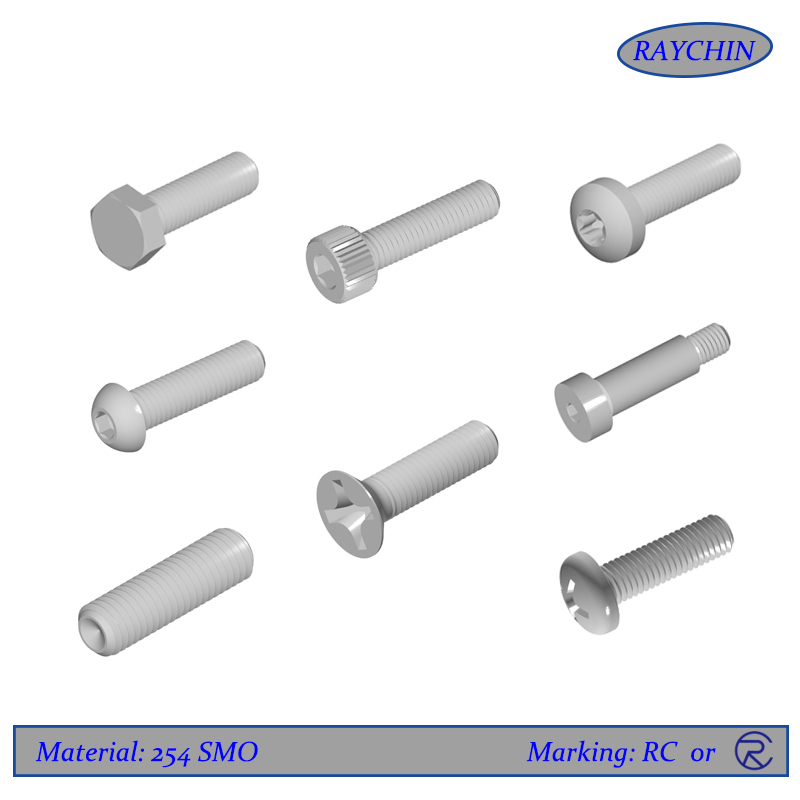

254 SMO Fasteners

254 SMO (1.4547) fasteners are made of a high-end stainless steel alloy that was developed for resistance to saltwater and chloride corrosion. This 6-Moly (6% Molybdenum) alloy has good localized corrosion resistance and 254 SMO provides much higher strength than other austenitic stainless steels. 254 SMO bolts are an ideal choice for high chloride environments including brackish water, seawater and other applications that demand heavy use of chlorines and chlorides. Compared to sister 6-Moly alloy AL6XN, 254 SMO fasteners offer slightly less high temperature stability corrosion resistance and strength.

Send Email Details -

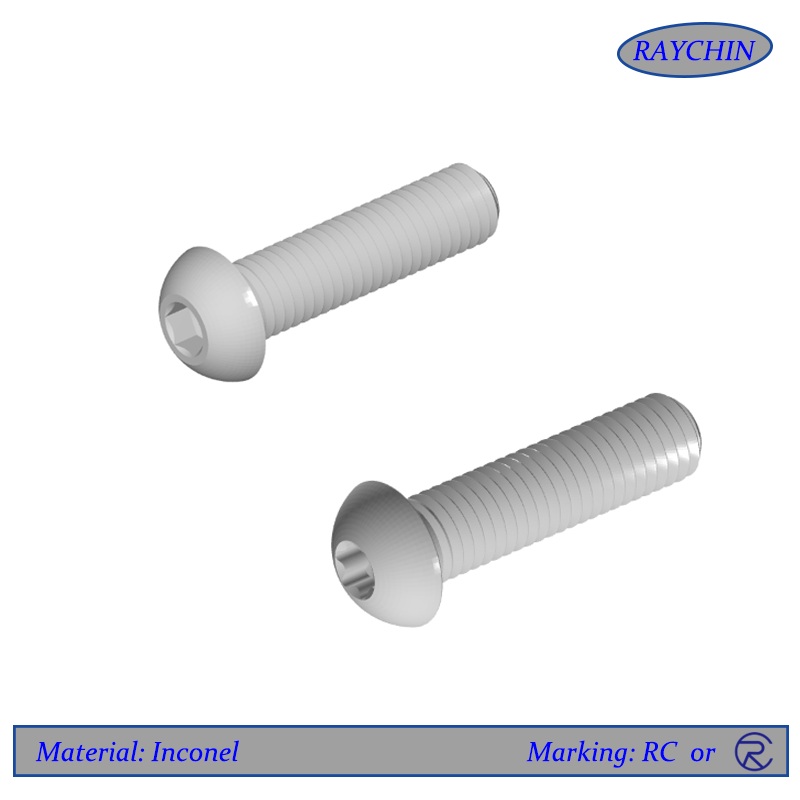

Inconel Button Head Cap Screws

Inconel® button head cap screws, like Inconel 600, 601,625,686,718 & 725 screws, are a family of nickel-chromium-molybdenum alloys used for their high strength at elevated temperatures and good corrosion resistance. Because of its high thermal stability, Inconel can be used in service temperatures ranging from cryogenic to 2200°F (982°C). The high alloy content of Inconel button head cap screws enable it to withstand a wide variety of severe corrosive environments. In mild environments, such as the atmosphere, sea water, neutral salts, and alkaline media, there is almost no attack to Inconel screws. In more severe corrosive environments the combination of nickel and chromium provides resistance to oxidizing chemicals, whereas the high nickel and molybdenum contents supply resistance to nonoxidizing environments.

Send Email Details -

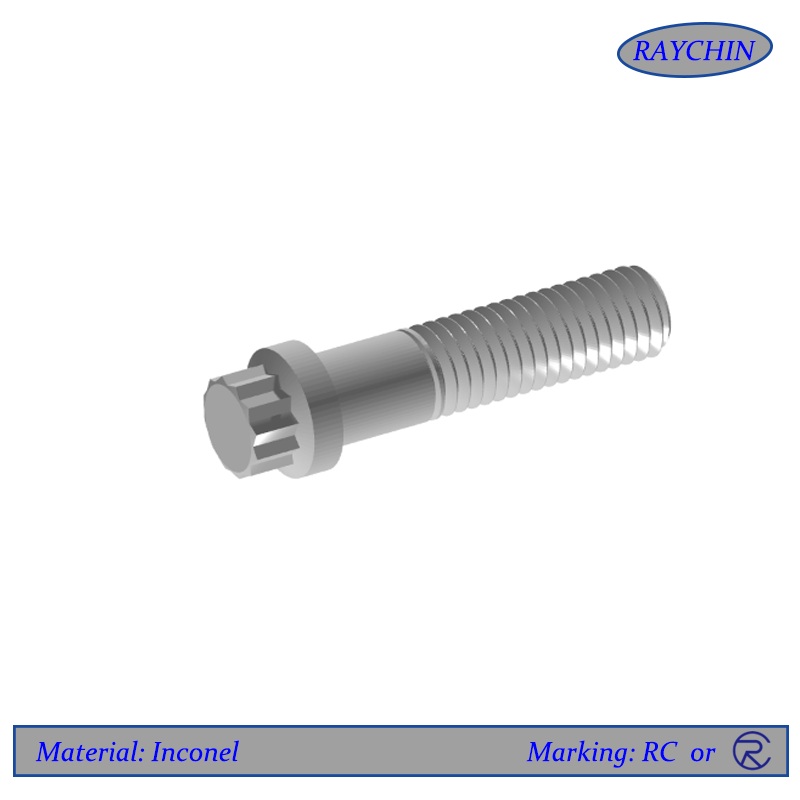

Inconel 12 Point Screws

Inconel® 12 point screws, like Inconel 600, 601,625,686,718 & 725 screws, are a family of nickel-chromium-molybdenum alloys used for their high strength at elevated temperatures and good corrosion resistance. Because of its high thermal stability, Inconel can be used in service temperatures ranging from cryogenic to 2200°F (982°C). The high alloy content of Inconel screws enable it to withstand a wide variety of severe corrosive environments. In mild environments, such as the atmosphere, sea water, neutral salts, and alkaline media, there is almost no attack to Inconel 12 point screws. In more severe corrosive environments the combination of nickel and chromium provides resistance to oxidizing chemicals, whereas the high nickel and molybdenum contents supply resistance to nonoxidizing environments.

Send Email Details -

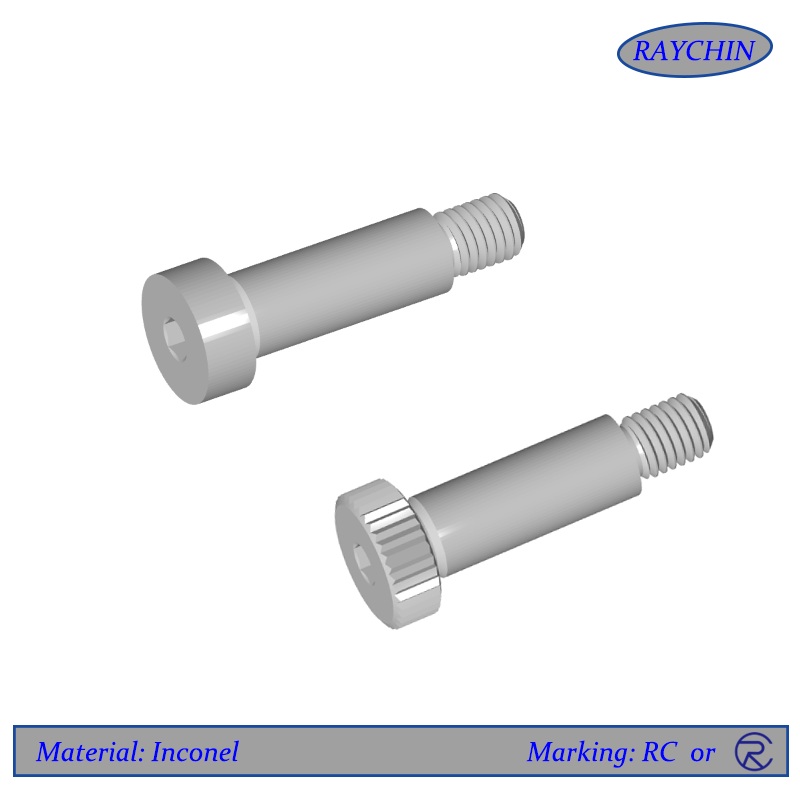

Inconel Shoulder Bolts

Inconel® shoulder bolts, like Inconel 600, 601,625,686,718 & 725 bolts, are a family of nickel-chromium-molybdenum alloys used for their high strength at elevated temperatures and good corrosion resistance. Because of its high thermal stability, Inconel can be used in service temperatures ranging from cryogenic to 2200°F (982°C). The high alloy content of Inconel bolts enable it to withstand a wide variety of severe corrosive environments. In mild environments, such as the atmosphere, sea water, neutral salts, and alkaline media, there is almost no attack to Inconel bolts shoulder. In more severe corrosive environments the combination of nickel and chromium provides resistance to oxidizing chemicals, whereas the high nickel and molybdenum contents supply resistance to nonoxidizing environments.

Send Email Details